Epoxy Concrete Repair Systems

Structural Injection, Patching & Filling for Damaged Concrete

Epoxy Concrete Repair

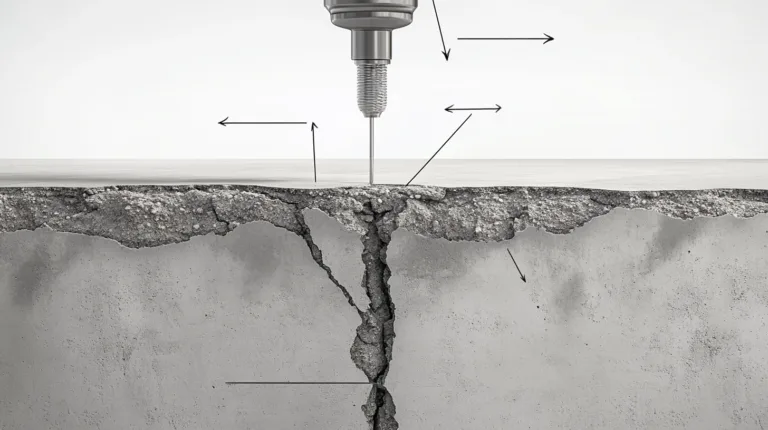

ZDSpoxy’s Epoxy Concrete Repair Systems are engineered for permanent structural rehabilitation of cracked, delaminated, or oil-contaminated concrete. Whether it’s injection sealing micro-cracks, patching spalled columns, or filling voids on wet substrates, our epoxy-based systems deliver high bond strength, chemical resistance, and zero shrinkage—even in the harshest conditions.

- No middlemen

- Fast prototyping

- Private label available

What Makes Concrete Repair Fail?

| Failure Mode | Common Cause | ZDSpoxy Fix |

| Crack reopens | Cement filler shrinks or weakens | Use structural epoxy injection (ZDS2002AB) |

| Delamination or blistering | Moisture behind repair area | Apply ZDS2870AB primer before patch |

| Peeling or chalking surface | Incompatible topcoat or UV damage | Use ZDS2186AB anti-yellowing topcoat |

| Repair doesn’t bond to oil | Oil residue in cracks or surface pores | Oil-tolerant injectable epoxy |

ZDSpoxy Repair System Matrix

| Problem Type | System Type | Recommended Product(s) |

| Hairline cracks (0.02–0.3 mm) | Injectable low-viscosity | ZDS2002AB, ZDS2013AB |

| Deep cracks (≥3mm) | Pourable epoxy grout | ZDS3382AB |

| Vertical or overhead repair | Knife-grade epoxy mortar | ZDS2771AB, ZDS1007AB |

| Oil-contaminated concrete | Oil-tolerant injection | ZDS2002AB |

| Wet substrate or underwater | Water-curing systems | ZDS1417AB, ZDS2013AB |

| Final coating or surface seal | Chemical/UV resistant topcoat | ZDS2186AB |

- Download TDS & SDS for All Models

- Request a Quote Based on Your Project

Why Epoxy Is Better for Structural Repair

- ✅ Penetrates Deep into Cracks (vs. surface-only fillers)

- ✅ High Bond Strength on Concrete & Steel

- ✅ Zero Shrinkage = No Reopening

- ✅ Resists Oil, Water, Acid, and Salt Spray

- ✅ Cures in Wet or Submerged Conditions

- ✅ Injection, Pourable & Knife-grade Options Available

Typical Repair Applications

- Structural beam or column crack injection

- Spalled concrete patching

- Oil-soaked garage floor repair

- Industrial floor joint edge rebuild

- Parking structure deck delamination fix

- Moisture-damaged cold room concrete repair

- Bridge deck waterproofing prep

- Seawall or port infrastructure crack sealing

Installation Guidance

- Injection systems: Use 2-part cartridge or pressure pot for 0.02–0.3mm cracks

- Knife-grade repair: Apply in layers, avoid thick fill at once

- Wet substrates: Prime with ZDS2870AB

- Underwater repair: Apply ZDS2013AB or ZDS1007AB using diver method or on wet surfaces

- Surface topcoating: Seal cured repair with ZDS2186AB for UV/chemical resistance

Use Case Highlight

A precast factory used ZDS2002AB to inject epoxy into 0.05mm cracks on an oil-exposed production slab.

In a separate project, ZDS2771AB was used to patch overhead spalling under a bridge deck without any sagging or slump.

Final surface coated with ZDS2186AB for chemical protection and clean finish.

Don’t just cover the cracks—repair them structurally.

ZDSpoxy concrete repair systems are engineered to last, and backed by full tech support, private label packaging, and project-matched advice.