Epoxy Coating Systems

High-Performance Surface Protection for Concrete, Steel & Marine Structures

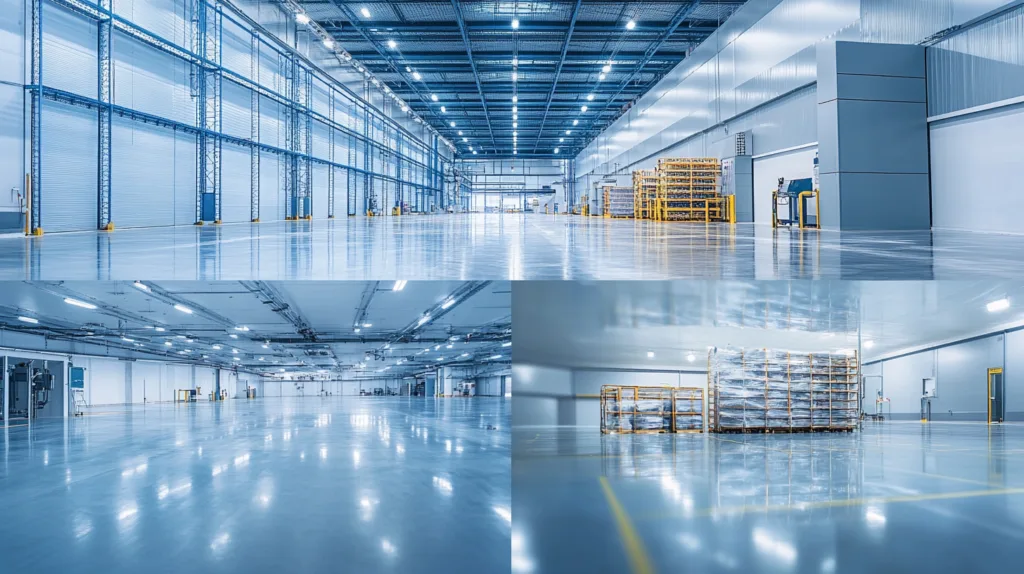

Epoxy Coating Solutions

When durability matters—ZDSpoxy Epoxy Coating Systems deliver.

Engineered for chemical resistance, UV stability, abrasion protection, and waterproof sealing, our coatings are trusted in factories, marine zones, flooring, and infrastructure where failure is not an option.

From anti-yellowing self-leveling finishes to underwater coatings and sealers, we provide field-proven epoxy systems that go beyond aesthetics—they protect your investment.

- No middlemen

- Fast prototyping

- Private label available

Common Problems with Low-Grade Coatings

| Problem | Risk | ZDSpoxy Solution |

| Yellowing under UV | Surface degradation & poor appearance | ZDS400-4 (anti-yellowing topcoat) |

| Peeling on damp surfaces | Poor adhesion & rework costs | ZDS2870AB primer for wet concrete |

| Blushing / whitening underwater | Coating failure in pools or marine zones | ZDS2186AB (non-blushing underwater coating) |

| Abrasion / chemical wear | Shortened lifespan in factories or tanks | ZDS400-4 / ZDS2186AB resistant coatings |

| Incompatible topcoat | Delamination from epoxy base | Matched ZDSpoxy systems only |

ZDSpoxy Coating System Lineup

- Download TDS & SDS for All Models

- Request a Quote Based on Your Project

Typical Coating Applications

- Industrial floor systems

- Marine structures (seawalls, ports)

- Underground tunnels and water tanks

- Concrete slab waterproofing

- Topcoat over grouting or patch repairs

- Cold-room and food-grade environments

- Structural steel anti-corrosion coating

Benefits of ZDSpoxy Coatings

- ✅ Anti-yellowing (outdoor or UV-exposed)

- ✅ Cures on Wet Surfaces

- ✅ Chemical and Salt Resistance

- ✅ Abrasion Resistant

- ✅ Solvent-Free Options

- ✅ Compatible with ZDSpoxy primers, grouts, and repair mortars

Application Notes

- Apply ZDS2870AB as primer when concrete is damp or porous

- Use ZDS400-4 for clean, bright, anti-yellowing finishes

- For marine/submerged use, apply ZDS2186AB by brush or roller

- Surface must be cleaned of laitance/oil/dust

- Pot life: 30–45 min depending on temperature

- Cure time: 8–24h; full chemical resistance: 3–7 days

Real Use Case

A food-grade floor contractor used ZDS400-4 as a self-leveling UV-stable topcoat over a high-strength epoxy mortar layer. No yellowing after 12 months of sun exposure.

In a separate marine project, ZDS2186AB was applied directly to seawall concrete in tidal zone (1.2–2.0m), without whitening or loss of adhesion.

Coatings are the final line of defense—don’t settle.

ZDSpoxy coating systems are built to seal, shield, and survive—in chemical plants, ports, tunnels, and more.