Flooring Resin Systems (Epoxy, PU, Polyaspartic)

- Decorative Looks And Finishes

- Resin Bound Stone Systems

- Anti-Static & ESD Epoxy Flooring

- Acid/alkali/solvent exposure

- Forklifts and heavy rolling

- No-demolition waterproof renovation

- Primer and substrate prep

- Sealers/topcoats comparison

What are flooring resin systems?

A flooring resin system is a layered floor solution, not a single coat. Each layer has a job.

Most resin floor systems include:

- Surface preparation (grinding / shot blasting)

- Primer (bonds to concrete and seals pores)

- Body layer (builds thickness and strength)

- Broadcast layer (optional) (adds texture / anti-slip / extra strength)

- Topcoat / sealer (final protection and appearance)

If one layer is missing or done wrong, the whole floor can fail early.

System types

Below are the most common resin flooring system families. Click into each hub for a deeper guide, recommended build-ups, and SKU options.

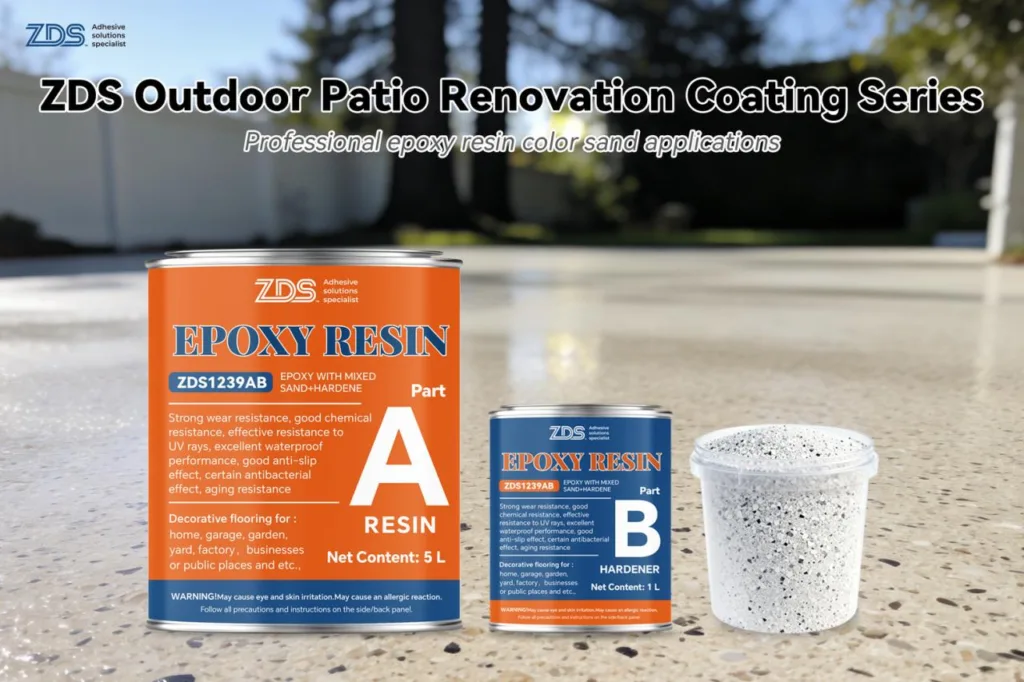

Decorative flooring systems

Decorative resin floors focus on looks + easy cleaning, while still offering strong durability. Common styles include metallic, flake, terrazzo, and colored sand.

Best for: showrooms, retail, lobbies, restaurants, offices, premium garages

Learn more: Decorative Flooring Systems

Resin bound stone systems

Resin bound stone is a permeable surface made by mixing stone aggregate with a resin binder, then sealing when needed. It’s popular outdoors because it supports drainage and gives a natural stone look.

Best for: sidewalks, driveways, parks, plazas, gardens, wet landscape areas

Learn more: Resin Bound Stone Systems

ESD / anti-static flooring systems

ESD (electrostatic discharge) floors are designed to control static electricity. A proper system includes a conductive path (often copper grid) and a conductive or dissipative layer.

Typical target range: 10⁵–10⁹ Ω surface resistance (project spec may vary).

Best for: electronics cleanrooms, assembly lines, labs, ESD work zones

Learn more: ESD & Anti-Static Epoxy Flooring Systems

Corrosion-resistant flooring systems

Corrosion-resistant resin floors create a dense barrier to help resist acids, alkalis, solvents, oils, and wet processing exposure. These systems usually require higher thickness and careful detailing at joints and drains.

Best for: chemical plants, battery rooms, containment zones, wet processing rooms

Learn more: Corrosion-Resistant Resin Flooring

Wear-resistant PU flooring systems

PU systems are often selected for high-frequency rolling loads and long-term abrasion exposure. With the right build-up, they can handle repeated forklift traffic and help reduce surface damage.

Best for: logistics centers, warehouses, forklift lanes, production corridors

Learn more: Wear-Resistant PU Flooring

Waterproofing & renovation coating systems

Renovation systems are built for repair + protection without demolition. They often combine repair materials + primer + topcoat, so you can upgrade old surfaces faster.

Best for: balconies, terraces, tile renovation, pools, old floors needing refresh

Learn more: Waterproofing & Renovation Coating Systems

1. What traffic will the floor see?

Add Your Heading Text Here

- Light (foot traffic): coating or self-leveling may work

- Medium (pallet jacks): stronger build-up, higher abrasion resistance

- Heavy (forklifts / impact): wear-resistant or mortar-type structures

2. Is the area wet, washed down, or underwater at times?

- Wet zones need waterproof layers and anti-slip textures

- Drain areas and corners need detail work (no shortcuts)

3. What chemicals can touch the floor?

List what’s on-site: oils, cleaners, acids, alkalis, solvents.

Then match the system with a chemical resistance design (and thickness).

4. Is UV exposure a concern?

5. How much downtime do you have?

- Longer downtime: more options

- Short downtime: choose faster curing routes and plan steps carefully

6. What finish do you want?

- Smooth gloss / matte

- Anti-slip texture

- Decorative effects (flake, metallic, terrazzo)

- Easy-clean, stain-resistant surface

Fast tip: If you’re unsure, start with the service conditions (traffic + water + chemicals). The “pretty layer” comes last.

Installation overview

Step 1: Site inspection

Check:

- Concrete strength and soundness

- Moisture condition

- Existing coatings (weak coatings must be removed)

- Oil contamination and cracks

Step 2: Substrate preparation

Common methods: grinding or shot blasting.

Goal: clean, open surface for strong adhesion.

Step 3: Repairs

Step 4: Primer

Step 5: Build-up layers

Step 6: Topcoat and curing

Step 7: Inspection and handover

Specs & testing

Specs help prevent misunderstandings and reduce callbacks. Common tests and metrics include:

- Adhesion strength (how well it bonds to concrete)

- Hardness (surface resistance to damage)

- Abrasion resistance (wear under traffic)

- Slip resistance (especially for wet zones)

- Chemical resistance (based on exposure list)

- Curing time / return-to-service time

- ESD resistance (for anti-static floors)

For ESD floors, many projects specify 10⁵–10⁹ Ω surface resistance and require documented test points.

Learn more: Specs & Testing for Resin Flooring: What to Measure

FAQ

How long do resin flooring systems last?

Do resin floors work on old concrete?

What is the most common reason for failure?

Can I make the floor anti-slip?

Which is better: epoxy, PU, or polyaspartic?

- Epoxy: strong, cost-effective, great for many indoor uses

- PU: often chosen for wear comfort, certain durability needs, and UV-stable finishing

- Polyaspartic: often selected when you want faster curing and strong topcoat performance

The best choice depends on traffic, chemicals, and downtime.

Get a ZDSpoxy recommendation (Fast)

Or send us these 4 answers:

- Indoor/outdoor + wet/chemical exposure

- Traffic type (foot / cart / forklift)

- Substrate (concrete / tile / stone)

- Desired finish (gloss/matte, color, anti-slip, UV)

We’ll reply with:

- A complete build-up (layer by layer)

- Matching product models under /product/

- Application steps + key checks

- A full technical package from our Download Center