Corrosion-Resistant Resin Flooring (For Harsh Chemical Areas)

Corrosion-Resistant Resin Flooring Solutions

- No middlemen

- Fast prototyping

- Private label available

Where this system is commonly used

This solution is built for harsh environments, such as:

- Chemical plants and corrosion-prone workshops

- Electroplating lines and pickling areas

- Wastewater treatment and chemical storage zones

- Battery and electronics chemical process areas

- Pharmaceutical and industrial cleaning zones

- Any area with frequent chemical spills, pooling, or long wet exposure

If your chemicals are unknown or changing, we can help you create a simple “chemical map” of your site before selection.

What problems this system solves

- Protects concrete from aggressive chemical contact

- Reduces blistering and delamination risk with proper barrier design

- Creates a seamless, cleanable surface (less dirt trap, easier washdown)

- Improves long-term durability in wet and harsh zones

- Helps control maintenance cost by preventing repeated patch repairs

Corrosion resistance vs. chemical resistance (quick clarity)

- Chemical resistant flooring is often for splashes + regular cleaning.

- Corrosion resistant flooring is for harsher chemicals, higher risk areas, and longer contact time—sometimes including pooling or immersion-like conditions.

If you have strong acids/alkalis, frequent spills, or long wet exposure, use a corrosion-resistant design.

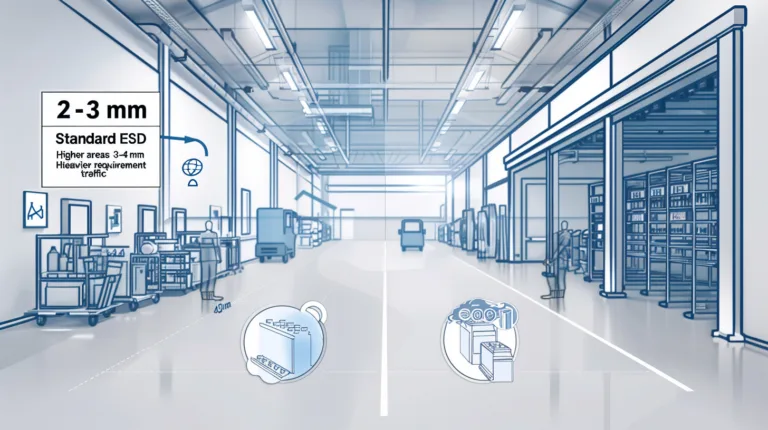

Thickness guide (simple selection)

Thickness is not just “more is better.” It should match the risk.

- 2–3 mm — Light to medium corrosion risk

(splashes, short contact time, controlled cleaning) - 3–6 mm — Heavy corrosion risk or long wet exposure

(frequent spills, pooling, harsh chemicals, higher safety requirement)

If your slab is weak, uneven, or cracked, we may add leveling or mortar layers to stabilize the base.

Recommended product models (ZDSpoxy)

Option A — Dense epoxy barrier coating system (common choice)

Best for many harsh chemical areas with strong daily performance needs.

System part | What it does | Recommended ZDSpoxy model |

Primer | Seals concrete, improves adhesion, reduces pinholes | ZDS1012AB — 2K Epoxy Primer |

Corrosion-resistant topcoat | Dense barrier + strong mechanical protection | ZDS4220AB-90 — Industrial-Grade Epoxy Topcoat |

When to choose this option

- You want a strong, cleanable, industrial finish

- Exposure is mostly splashes + regular washdown

You want a simpler build-up with reliable performance

Option B — Heavy-duty corrosion mortar + barrier top system (for higher risk)

System part | What it does | Recommended ZDSpoxy model |

Primer for mortar system | Strong base for thick build-ups | ZDS5502AB — PU Mortar Flooring System Primer |

Corrosion-resistant mortar layer | Builds thickness + improves barrier stability | ZDS2802-PU — Chemical/Corrosion Resistant Mortar Layer |

Protective top layer | Seals surface and improves cleanability | ZDS4220AB-90 — Industrial-Grade Epoxy Topcoat |

When to choose this option

- You have frequent spills, pooling, or long wet contact

- You need 3–6 mm thickness for durability

The slab needs extra strengthening and protection

Installation overview (what to expect)

A corrosion-resistant floor succeeds when the basics are done right:

Chemical review (fast but critical)

We confirm your chemical list (name, concentration, temperature) and exposure type (splashes vs pooling).Surface preparation (the make-or-break step)

Grinding or shot blasting removes weak layers and contaminants. Cracks and joints are repaired.Primer application

Seals the slab and supports strong bonding.Build the barrier body layer

Mortar/leveling layers (if needed) help reach the target thickness and reduce weak spots.Top layer / sealer

Creates the final corrosion-resistant surface that is easy to clean.Curing and return-to-service plan

We provide a simple plan based on temperature, ventilation, and your reopening time.

Quality checks (how you verify performance)

Before handover, focus on checks that prevent early failure:

- Thickness check (matches the 2–3 mm or 3–6 mm design target)

- Continuity check (no pinholes, no missed areas, stable film build)

- Adhesion / bond strength (especially at repairs, edges, drains)

- Visual inspection (bubbles, soft spots, rough zones, weak joints)

- Trial cleaning / chemical wipe test (if your process requires it)

If your site has a strict QA process, we can align checks with your internal acceptance workflow.

Common failures (and how to avoid them)

Problem: Blistering or bubbling

Common causes: moisture vapor, poor surface prep, trapped air.

Avoid: moisture check, correct prep, proper primer and layer control.

Problem: Soft spots or staining

Common causes: wrong resin type for the chemical list, or under-built thickness.

Avoid: confirm chemicals first, then choose the right build-up.

Problem: Peeling at joints and edges

Common causes: weak concrete, contamination, wrong joint treatment.

Avoid: repair plan + joint detail + correct primer selection.

FAQs

Do I need 6 mm thickness for corrosion resistance?

Can you design different thicknesses in one facility?

What information do you need to recommend the right system?

Get a recommendation

Send us these 5 details, and we’ll recommend the safest corrosion-resistant system:

- Industry + area (plating line, storage, wastewater, battery, etc.)

- Chemical list (name + concentration + temperature)

- Exposure type (splashes / pooling / long wet contact)

- Traffic (people, carts, forklifts)

- Target thickness (2–3 mm or 3–6 mm)

ZDSpoxy will provide a clear system build-up + recommended product models + simple application notes for your project.