Chemical Resistant Resin Flooring (Acid & Alkali Protection)

Chemical Resistant Resin Flooring Solutions

- No middlemen

- Fast prototyping

- Private label available

Where this system is commonly used

This solution is a good fit for sites that face frequent chemicals, cleaning agents, and industrial liquids, such as:

- Chemical plants and fine chemical workshops

- Electroplating and surface treatment areas

- Food processing and pharmaceutical facilities

- Laboratories and testing centers

- Battery and electronics manufacturing

- Wastewater treatment and industrial buildings

What this system helps you achieve

- Better resistance to acids and alkalis (built for long-term stability)

- Dense, seamless surface that is easier to clean

- High mechanical strength for daily traffic

- Good adhesion to prepared concrete

- Long service life with correct system design and installation

Chemical resistance scope (simple explanation)

This system is designed for areas where floors may face:

- Acid/alkali solutions and splashes

- Chemical cleaning agents

- Industrial process liquids

If you have long-term immersion, strong solvents, or extreme conditions, we can upgrade the build-up and recommend a more heavy-duty system.

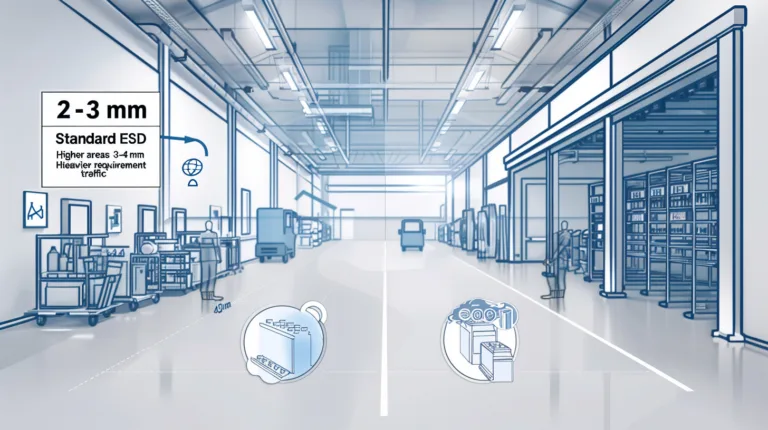

Thickness guide (simple selection)

Choose thickness by chemical severity and mechanical load:

- 2.0 mm — Moderate chemical exposure

(splashes, routine cleaning, controlled process areas) - 2.5–3.0 mm — Heavy acid/alkali exposure or long-term wet areas

(more frequent spills, higher risk, tougher service)

Thickness can be adjusted based on your chemical type, concentration, spill frequency, and traffic.

Recommended product models (ZDSpoxy)

Option A — Chemical-resistant epoxy coating system (common choice)

System part | What it does | Recommended ZDSpoxy model |

Epoxy primer | Seals concrete and improves bonding | ZDS1012AB — 2K Epoxy Primer |

Chemical-resistant topcoat | Dense barrier + wear resistance | ZDS4220AB-90 — Industrial-Grade Epoxy Topcoat |

Option B — Heavy-duty chemical resistant mortar system (for tougher environments)

| System part | What it does | Recommended ZDSpoxy model |

| PU mortar primer | Strong base for mortar system | ZDS5502AB — PU Mortar Flooring System Primer |

| Chemical resistant mortar layer | Builds thickness and improves resistance and strength | ZDS2802-PU — Chemical Resistant Resin Flooring Mortar Layer |

| Protective top layer (as needed) | Adds barrier + easier cleaning | ZDS4220AB-90 — Industrial-Grade Epoxy Topcoat (common choice) |

Installation overview (what to expect)

Chemical & risk review

We confirm your exposure type: splashes vs frequent spills vs long-term wet/immersion.Surface preparation (critical step)

Grinding or shot blasting removes weak concrete, opens pores, and improves bonding. Cracks and joints are repaired.Primer application

Seals the concrete and reduces pinholes and blistering risk.Build thickness (if needed)

Mortar/leveling layers improve flatness, strength, and barrier consistency.Apply chemical resistant topcoat

Creates a dense, seamless protective surface.Curing and return to service

Cure time depends on temperature and ventilation. We provide a simple curing plan for your schedule.

Quality checks (how you verify performance)

Before handover, these checks help confirm real performance:

- Adhesion / bond strength (especially repaired areas and edges)

- Coating continuity (no pinholes, weak spots, or missed areas)

- Thickness check (matches the 2.0mm or 2.5–3.0mm design target)

- Visual inspection (bubbles, delamination signs, rough patches)

- Trial cleaning / chemical wipe test (when required by your process)

If you need a formal acceptance checklist, we can provide one.

Common failures (and how to avoid them)

Problem: Blistering or bubbling

Often caused by moisture vapor, poor prep, or trapped air in porous concrete.

Fix: moisture check + correct preparation + proper priming.

Problem: Peeling at edges or joints

Often caused by weak concrete, contamination, or poor joint treatment.

Fix: repair + joint plan + correct primer selection.

Problem: Staining or soft spots

Often caused by the wrong resin type for the chemical list.

Fix: confirm chemical list first, then choose the correct build-up.

FAQs

Is epoxy enough for acid/alkali areas?

Can this floor handle frequent washdown?

What details do you need to recommend the right system?

Get a recommendation

Send us these 5 details, and we’ll recommend the right chemical resistant system and matching product models:

- Industry and area (electroplating, lab, battery, chemical plant, etc.)

- Chemical list (name + concentration)

- Exposure type (splashes / frequent spills / long-term wet)

- Traffic load (people, carts, forklifts)

- Target thickness (2.0mm or 2.5–3.0mm)

ZDSpoxy will provide a clear system build-up + recommended product set + application notes for your project.