Antimicrobial Resin Flooring (Hygienic, Seamless, Easy to Clean)

Antimicrobial Resin Flooring Solutions

- No middlemen

- Fast prototyping

- Private label available

Where antimicrobial resin flooring is used

This system is a strong fit for areas that require strict hygiene and frequent cleaning, such as:

- Food processing and packaging facilities

- Pharmaceutical plants and GMP areas

- Laboratories and research centers

- Healthcare spaces and clean environments

- Cold storage and fresh-product handling areas

- Cosmetics and personal care production sites

If your site has washdown zones, wet areas, or strong cleaning routines, we can tune the system for that.

What this system helps you achieve

- Antibacterial protection to help reduce microbial growth on the surface

- Mold resistance for cleaner, more stable environments

- Seamless finish that is easier to wash and disinfect

- Low porosity that reduces dirt and liquid penetration

- Strong adhesion and durability with correct design and installation

- Better long-term appearance under frequent cleaning

Key performance targets (simple, buyer-friendly)

Most antimicrobial resin flooring projects focus on clear, measurable goals:

- Antibacterial rate: ≥99%

- Mold resistance: designed to support “no visible growth” performance

- Easy cleaning: smooth, joint-free surface

- Washdown durability: built for frequent cleaning routines

- Slip control: adjustable to match wet or dry operation

The best system is not only about “antimicrobial additives.” It is also about a dense surface, correct thickness, and correct detailing around drains, corners, and joints.

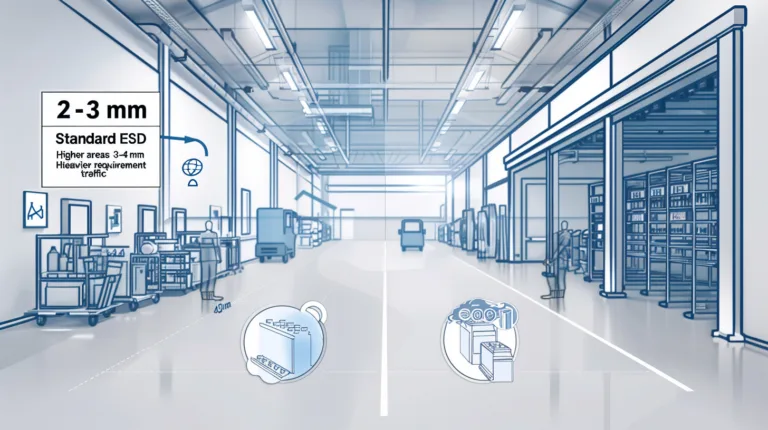

Thickness guide (simple selection)

Choose thickness based on hygiene level, cleaning frequency, and load:

- 2.0 mm — Standard hygienic areas

(routine cleaning, general production zones) - 2.5–3.0 mm — Higher hygiene requirement or frequent washdown

(more water, stronger cleaners, more traffic or stricter standards)

If you have heavy carts, wet zones, or strong disinfectants, we recommend the higher range for better long-term stability.

Recommended product models (ZDSpoxy)

Option A — Antimicrobial epoxy coating system (common choice)

| System part | What it does | Recommended ZDSpoxy model |

| Epoxy primer | Seals concrete and improves bonding | ZDS1012AB — 2K Epoxy Primer |

| Antimicrobial topcoat | Seamless finish with hygiene-focused performance | ZDS5201AB — Antimicrobial Resin Flooring Topcoat |

Option B — Antimicrobial mortar build-up (for higher washdown / stronger demand)

| System part | What it does | Recommended ZDSpoxy model |

| Primer for build-up system | Strong base for thicker layers | ZDS1012AB — 2K Epoxy Primer (common primer choice) |

| Antimicrobial mortar/body layer | Adds thickness and improves surface stability | ZDS5202 — Antimicrobial Resin Flooring Mortar Layer |

| Antimicrobial finish layer | Final hygienic, seamless working surface | ZDS5201AB — Antimicrobial Resin Flooring Topcoat |

Quick selection

- Standard production hygiene → Option A

- Wet washdown + stronger cleaning + higher hygiene → Option B

Installation overview (what to expect)

Hygiene and cleaning review

We confirm cleaning frequency, water exposure, disinfectants, and slip needs.Surface preparation (critical step)

Grinding or shot blasting removes weak layers and contaminants. Repairs are completed before coating.Primer application

Seals the slab and reduces pinholes.Build the body layer (if needed)

Creates a dense, consistent surface, especially important for washdown zones.Apply antimicrobial finish

Creates the final seamless surface.Curing and reopening plan

We provide a simple plan based on your schedule, temperature, and ventilation.

Quality checks (how you verify performance)

Before handover, focus on checks that support hygiene and durability:

- Surface continuity (no pinholes, no open pores, no weak spots)

- Thickness check (2.0mm or 2.5–3.0mm target)

- Adhesion check (especially repaired zones and edges)

- Slip level check (match wet/dry operation needs)

- Visual inspection (smoothness, uniform finish, clean detailing)

- Trial cleaning (optional, based on your process)

If you need a formal hygiene acceptance checklist, we can provide one.

Common problems (and how we prevent them)

Problem: Stains or trapped dirt

Often caused by porosity, pinholes, or poor detailing at corners/drains.

Fix: correct prep + sealing + detail work.

Problem: Slippery floor in wet areas

Often caused by choosing a finish that is too smooth.

Fix: controlled texture design that stays cleanable.

Problem: Peeling at edges

Often caused by weak substrate or poor prep.

Fix: repair plan + correct primer + correct curing control.

FAQs

Does antimicrobial flooring replace cleaning?

Can you make it non-slip and still easy to clean?

What information do you need for a system recommendation?

Get a recommendation

Send us these 5 details, and we’ll recommend the right antimicrobial flooring system:

- Industry (food, pharma, lab, cosmetics, etc.)

- Cleaning routine (washdown? disinfectants?)

- Wet or dry operation (and slip requirements)

- Traffic (people, carts, forklifts)

- Target thickness (2.0mm or 2.5–3.0mm)

ZDSpoxy will provide a clear system build-up + recommended product models + application notes for your hygienic facility.