Introduction to Shore D Hardness, Impact Resistance, Scratch Resistance

Epoxy resin flooring has changed the way industries and homeowners think about surface durability. At the heart of this transformation is an easily overlooked, yet vital property—Shore D hardness. But hardness by itself is only one piece of a complex puzzle. To create a floor that truly stands up to the demands of daily life or industrial use, it’s just as important to consider impact resistance and scratch resistance. This article explains why Shore D hardness matters, how it interacts with other resin properties, and what every buyer should know before making a decision.

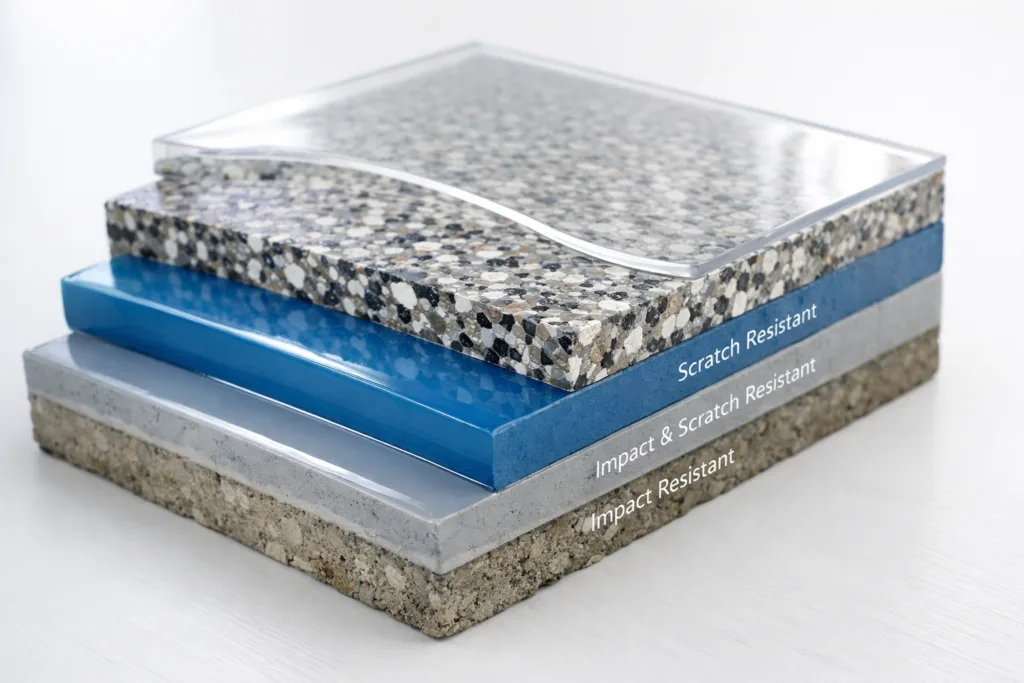

What Is Shore D Hardness?

Shore D hardness is a standardized measurement of how resistant a material is to being dented, scratched, or indented by sharp objects. It’s tested using a Shore durometer, which applies a specific force using a defined probe shape. The Shore D scale is designed for hard plastics and resins—including high-performance epoxy floor coatings. The higher the Shore D number (ranging from about 41 to 90 for most resins), the harder—and initially, the more resistant—a resin feels under pressure.

The Science Behind Hardness Ratings

Hardness, in the context of flooring materials like epoxy, refers to the surface’s ability to resist penetration or permanent deformation. This property is vital for withstanding short-term pressure, such as point loads from equipment or falling tools. However, hardness is only a snapshot of one performance aspect, not a full guarantee of total durability.

How Shore D Hardness Is Tested

The Shore D test involves pressing a hard steel point into the resin sample at a controlled pressure. The depth of this penetration is read as a number on the Shore D scale. Laboratories follow international standards, like ASTM D2240, to ensure consistency. For reliable comparison, samples should be fully cured and tested at specific temperatures.

The Role of Impact Resistance in Epoxy Flooring

Impact resistance defines how well an epoxy coating can absorb a sudden force, such as a dropped tool or a rolling cart. Materials with very high Shore D hardness can sometimes crack or shatter under high impact, while those balanced with toughness can flex and recover. The best resin floor isn’t always the hardest; it’s the one that survives real-world stress without chipping or breaking.

Understanding Scratch Resistance in Resin Floors

Scratch resistance is the coating’s ability to withstand wear from dragging, scraping, or abrasive actions. While harder floors (higher Shore D) often resist minor scratches better, excessive brittleness can lead to unsightly surface marks. Epoxy systems usually use a combination of additives and cross-linking chemistries to achieve a balance between scratch resistance and durability.

The Interplay: Hardness vs. Toughness

The trade-off between Shore D hardness and impact resistance is a practical reality. Harder isn’t always better. A super-hard floor might resist surface dents but could fail catastrophically under force. That’s why resin formulators experiment with different curing agents and additives—to achieve optimum ratios for specific applications, whether it’s a machine shop or a residential garage.

Why Balance Matters: Practical Implications

Many people assume a high Shore D hardness rating guarantees long life. However, without proper flex or toughness, overly hard resins may crack where resilient ones would recover. For commercial kitchens or warehouses, look for products that balance a tough, flexible matrix with sufficient surface hardness to handle both impact and abrasion.

Table: Comparing Shore D Hardness, Impact Resistance, and Scratch Resistance

| Property | What It Measures | Typical Range (Epoxy Floor) | Real-World Benefit |

|---|---|---|---|

| Shore D Hardness | Surface resistance to denting | 70–90 | Minimizes surface wear from heavy loads |

| Impact Resistance | Ability to absorb sudden force | Good–Excellent (varies) | Prevents cracking/chipping from dropped objects |

| Scratch Resistance | Resistance to abrasive scratches | Moderate–High (with topcoats) | Resists marks from wheels/foot traffic |

Hardness Ratings in Everyday Use

For a homeowner or facility manager, Shore D hardness matters during daily operations—a higher value means fewer chair or tool dents. However, it doesn’t directly predict how a floor will handle repeated impact or heavy rolling carts. Many modern systems include wear-resistant topcoats to improve scratch resistance even further.

How Formulations Influence Shore D Hardness

Epoxy resin formulators select base resins, hardeners, and modifiers to influence not just the cured Shore D rating but also workability, cure speed, and final toughness. A floor coating like ZDS-1012ab illustrates how the right formulation ensures both adhesion and a balanced profile between hardness and resiliency.

Choosing the Right Epoxy Resin by Application

Not every floor needs maximum hardness. For electronics or cleanroom use, antistatic and abrasion resistance may be top priorities. Industrial workshops might need high impact resistance against heavy equipment. Decorative systems favor a blend of scratch resistance and visual appeal.

Industrial vs. Residential Settings: Key Differences

Industrial floors deal with harsh wear, so higher Shore D and impact resistance are typical. For homes or light commercial spaces, a slightly lower Shore D (but higher scratch resistance) might perform better, especially when comfort and safety are concerns. A solution like antimicrobial resin flooring showcases this—providing hygienic, durable protection tailored to lighter use environments.

Shore D Hardness in Polyurethane and Polyaspartic

Although epoxy is the benchmark for hard, tough floors, certain polyurethane and polyaspartic coatings can offer matching or superior flexibility, especially at lower temperatures. This makes them attractive for spaces needing both surface hardness and flexibility. For example, ZDS-8300AB polyurethane topcoats deliver notable chemical and scratch resistance, extending system life.

Which Hardness Level Is Best?

It’s tempting to aim for the highest Shore D value possible, but optimal results come from matching the system’s balance to the real site demands. ZDSpoxy product ranges illustrate how selecting for substrate, service conditions, and environmental exposures produces longer-lasting floors than a “highest number wins” strategy.

The Limits of Shore D Hardness

Very high Shore D scores can mean brittleness, especially for large or cold environments. Expansion, contraction, vibration, and substrate movement all become risks if the resin system lacks flexibility. A holistic approach, blending hardness with impact absorption, is key for durability.

How to Read Epoxy Resin Data Sheets

Data sheets disclose the Shore D rating, but always look for complementary values—such as compressive strength, flexural modulus, and elongation at break. Reading beyond the headline numbers lets you compare total durability and suitability for specific needs.

How ZDSpoxy Approaches Real-World Performance

From an engineering point of view, ZDSpoxy considers more than just lab numbers. Preparation, mixing accuracy, and environmental factors like temperature and substrate dampness all affect a resin’s ability to reach its intended Shore D hardness. On large projects, controlling batch sizes and monitoring application variables sharply reduces the chance of early failures or inconsistent surface hardness. Trade-offs—such as accepting slightly lower hardness in exchange for higher flexibility—are sometimes made for floors exposed to rapid temperature swings or vibration.

Common Application Issues with Hard and Brittle Resins

Epoxy systems that are too hard can become brittle, leading to chipping, crazing, or interlayer delamination. These failures may result from poor substrate prep, incorrect mixing, or ignoring site conditions—such as moisture in concrete, which can undermine even the toughest resins.

The Importance of Adhesion for Surface Hardness

Even if a resin is hard, its performance depends on strong adhesion to the substrate. A tough, well-bonded underlayer ensures that heavy impacts are distributed, minimizing surface cracks. Primers with moderate hardness levels, like ZDS-105, often build better bonds for topcoats, which can then deliver higher scratch resistance without risking early detachment.

Scratch Resistance: Chemistry and Maintenance

Scratch resistance is not just about raw hardness; particle size of fillers, choice of curing agents, and even surface gloss all play roles. Some systems use micro-abrasive resistant additives. Regular cleaning with non-abrasive tools, coupled with avoidance of sharp or rolling debris, helps extend a resin floor’s life and preserve appearance.

Innovations in Impact and Scratch Resilience

Recent advances include hybrid coatings and nanotechnology additives that toughen the matrix without sacrificing Shore D performance. For facilities with routine abuse—like prep kitchens or warehouses—these new materials mean fewer gouges and lower repair costs over time.

Recommended Testing and Maintenance Practices

Routine testing of Shore D hardness (post-installation) provides early warnings of under-performing coatings, especially in harsh-use areas. Simple practices—such as spot repairs, quick scratch touch-ups, or periodic re-topcoating—can keep floors at peak durability for years.

Case Studies: Balancing Shore D Hardness in Complex Projects

In heavy-duty sites such as production facilities, a dual-layer system may combine a tough, flexible base with a high-hardness topcoat. On the other hand, schools or offices may trade some surface hardness for extra comfort and slip resistance.

Shore D Hardness, Impact Resistance, Scratch Resistance

These three qualities form the backbone of high-performance resin floors. When harmonized, they deliver a floor that resists daily hazards, looks good for years, and reduces long-term costs. Choosing the right system takes more than scanning for the highest number—it requires a full understanding of use conditions and system chemistry.

Conclusion

Shore D hardness is central to the performance of epoxy flooring, but it’s only one of several properties to consider. Balancing hardness with impact and scratch resistance means longer, safer, and more visually appealing floors. For both buyers and specifiers, looking beyond surface ratings and focusing on real-world performance is the sure path to durable, value-driven flooring choices.

Frequently Asked Questions

What does Shore D hardness mean for epoxy floors?

Shore D hardness measures how resistant an epoxy floor is to indentation or surface damage. It reflects the coating’s ability to withstand load and daily wear, helping predict longevity.

Does a higher Shore D rating always mean better durability?

Not always—while a higher Shore D score means greater surface hardness, it can also mean brittleness. The best durability comes from balancing hardness with toughness and impact resistance.

How does impact resistance differ from hardness in flooring?

Impact resistance shows how well a floor absorbs sudden forces without cracking or chipping, while hardness focuses on resisting slow, steady pressure or abrasion. Both are essential for long-lasting floors.

What can affect the Shore D rating in real installations?

Factors such as mixing accuracy, substrate moisture, cure temperature, and application methods all influence final Shore D hardness. Proper prep and application are key for reaching target ratings.

How do I choose the right hardness for my space?

Assess your setting: Heavy industry favors higher Shore D and impact resistance, while homes may benefit from a more flexible, scratch-resistant system. Match the resin system to actual usage needs.

Is scratch resistance only determined by hardness?

No—scratch resistance depends on surface chemistry, fillers, curing process, and maintenance. Some moderately hard floors outperform very hard ones due to superior formulation and additives.