Anti-Yellowing Epoxy Topcoat

Long-Lasting Clarity. Built for Harsh Environments.

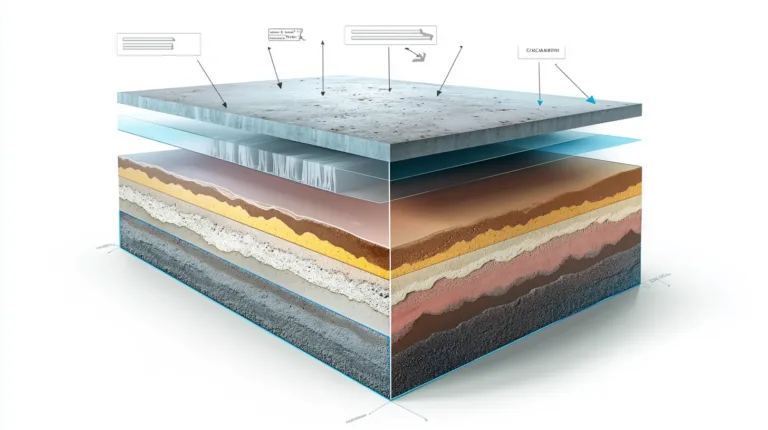

Anti-Yellowing Epoxy Topcoat Solutions

Yellowing is the silent killer of beautiful concrete surfaces.

UV rays, moisture, and heat break down conventional epoxy—leaving floors faded, yellow, and dull.

ZDSpoxy anti-yellowing topcoats are engineered for durability and visual performance. Whether you’re coating showrooms, marine structures, or high-glare industrial floors, you’ll get a UV-stable, high-gloss finish that stays clear—year after year.

- No middlemen

- Fast prototyping

- Private label available

Why Epoxy Topcoats Turn Yellow (And How ZDSpoxy Solves It)

Problem | Conventional Epoxy | ZDSpoxy Anti-Yellowing Topcoat |

UV exposure | Turns amber in months | UV inhibitors + nano fillers |

High-temperature zones | Accelerates yellowing | Heat-stable molecular matrix |

Moisture or chemical splash | Dulls clarity, chalks | Hydrophobic + chemical resistant |

Outdoor or semi-outdoor application | Not recommended | Designed for harsh environments |

Recommended Product: ZDS400-4

| Property | Value |

| Gloss | 92 GU (60°) |

| UV Resistance | No yellowing after 1000h QUV |

| Hardness | Shore D 82 |

| Chemical Resistance | Strong acids, bleach, ethanol |

| Viscosity | 800–1200 cps |

| Recoat Window | 6–24 hours |

| Application | Roller / squeegee / spray |

| Curing Time (25°C) | Touch-dry: 3 hrs / Full: 24 hrs |

Where Anti-Yellowing Topcoats Matter Most

- Showroom & retail floors (optical clarity over design finishes)

- High-bay warehouses (natural light exposure)

- Commercial kitchens (hot oil, steam, bleach cleaning)

- Yacht decks & marine coatings (UV + saltwater + gloss retention)

- Bridge decks & precast elements (public-facing concrete)

- Bright epoxy art or floor graphics sealing

- Epoxy floors in tropical or desert climates

Application Tips

- Always apply over fully cured grout or primer layer

- Use lint-free roller to avoid micro-bubbles

- Avoid application under direct sun (ideal: morning or shaded)

- Mix Part A + B exactly as specified, overmixing can introduce haze

- Optional: Add silica matte agent for satin finish

Comparison with Polyaspartic & PU

| Feature | Epoxy (ZDSpoxy) | Polyaspartic | Polyurethane |

| Yellowing | Excellent | Excellent | Poor to moderate |

| Gloss Retention | High | High | Medium |

| Recoat Window | Flexible | Very short | Moderate |

| Cost | Moderate | High | Low |

| Odor | Low | Moderate | High |

Case Example: Yacht Refurbishment (Thailand)

A luxury yacht maintenance company required a high-gloss, anti-yellowing topcoat for UV-exposed deck surfaces.

They selected ZDS400-4 for its marine-grade UV blockers and durability.

- 🔧 Application by roller on top of marine-grade epoxy base

- 🌊 Passed 72-hour salt-spray and bleach-resistance test

- 📷 12-month follow-up showed zero ambering or gloss loss

- 👍 Client adopted ZDS400-4 as standard for all upper-deck refurbishments

FAQs

Will it stay clear in full sunlight?

Yes. ZDS400-4 is QUV-tested for 1000h exposure with no visible yellowing.

Can it be used on decorative epoxy floors with flakes or metallic pigments?

Absolutely. It enhances the appearance while preserving true color.

How does it perform against bleach or kitchen cleaners?

It is highly chemical resistant—no dulling or chalking.

Tired of watching your beautiful epoxy finish fade to yellow?

ZDSpoxy ZDS400-4 keeps surfaces clear, glossy, and protected for the long run.