Bridge Crack Injection Repair

Structural Epoxy Resin Systems for Long-Term Bridge Durability

Bridge Crack Injection Repair Solutions

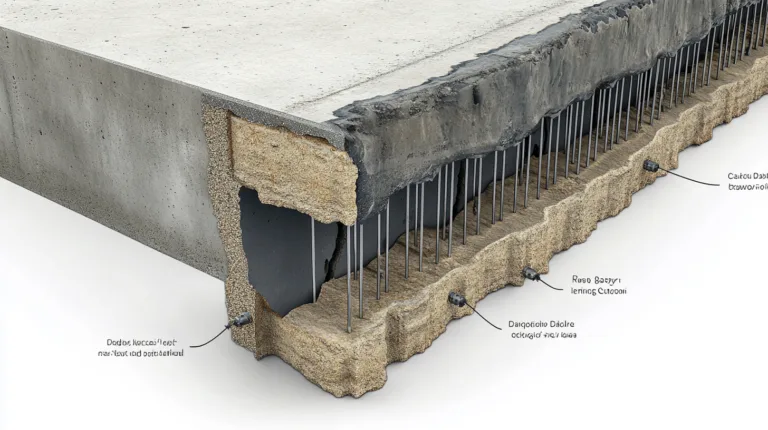

Bridge cracks aren’t just cosmetic—they’re signs of structural stress, freeze-thaw damage, rebar corrosion, or loading fatigue.

If left untreated, they widen, leak, and compromise the bridge’s lifespan.

ZDSpoxy’s crack injection systems restore integrity by sealing microcracks (0.02–2mm), bonding fractured concrete, and protecting against future water ingress or corrosion—even in wet or oil-contaminated environments.

- No middlemen

- Fast prototyping

- Private label available

Common Bridge Crack Issues & Causes

| Crack Type | Likely Cause | Risk if Ignored |

| Hairline vertical cracks | Shrinkage, temperature variation | Water seepage, freeze-thaw degradation |

| Diagonal cracks near supports | Shear stress or deflection | Structural weakening |

| Horizontal deck cracks | Rebar expansion or fatigue | Corrosion, slab failure |

| Water seepage through joints | Poor sealing or movement | Bearing damage, spalling |

Why Use ZDSpoxy Epoxy Injection?

- ✅ Deep crack penetration (0.02–2mm)

- ✅ Structural-grade bonding strength (>2.5 MPa pull-off)

- ✅ Zero shrinkage = long-term seal

- ✅ Cures on damp or oily concrete

- ✅ Low viscosity = easy pump or cartridge injection

- ✅ Compatible with vertical, overhead, or horizontal repairs

- ✅ Works in tunnels, decks, piers, and supports

Recommended ZDSpoxy Injection Products

| Model | Description | Application |

| ZDS2002AB | Ultra-low viscosity, oil-tolerant | Active cracks, contaminated concrete |

| ZDS2013AB | Water-curing injectable epoxy | Submerged or wet bridge cracks |

| ZDS2771AB | Knife-grade epoxy repair mortar | Surface crack widening, corner build-up |

| ZDS2870AB | Moisture-tolerant primer | Damp concrete surfaces before injection |

Installation Overview

- Clean crack surfaces (remove debris/oil with wire brush or solvent)

- Place surface ports at regular intervals (every 15–30cm)

- Seal crack path with epoxy paste

- Inject resin from bottom up using cartridge or pressure pot

- Monitor for full crack fill (resin appears at upper port)

- Allow full cure (24–48h) before reopening structure

Don’t let small cracks become major failures.

ZDSpoxy’s bridge crack repair systems offer engineered performance, precise delivery, and long-term durability for infrastructure assets.