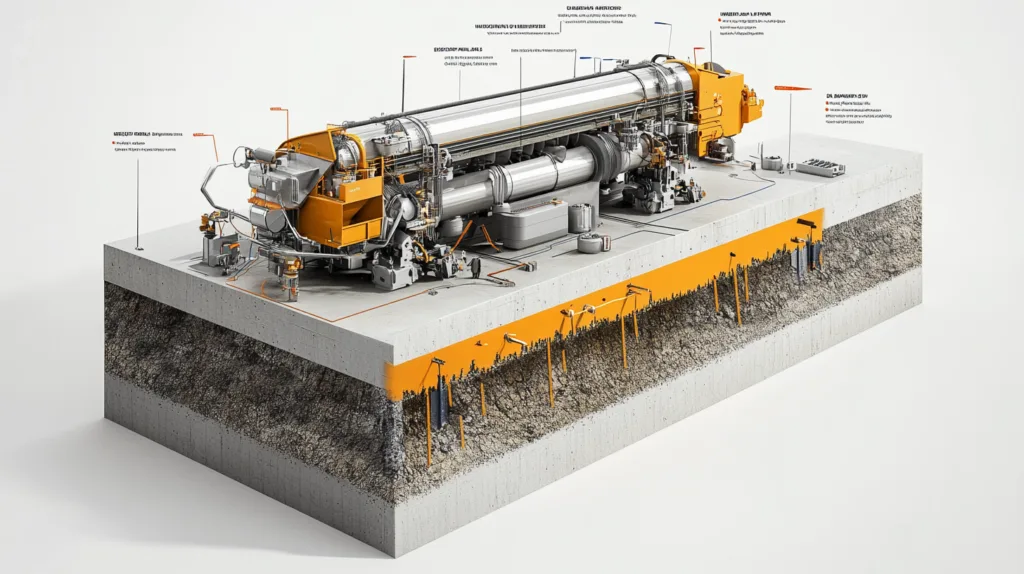

Crusher & Compressor Base Grouting

High-Strength, Vibration-Resistant Grout Systems for Dynamic Machines

Crusher & Compressor Base Grouting Solutions

Crushers and compressors don’t sit still—your foundation grout can’t either.

ZDSpoxy’s epoxy grout systems are purpose-built for vibration-intensive and shock-loaded equipment foundations. Whether you’re installing a rotary crusher, reciprocating compressor, or impact mill, we help ensure stable alignment, zero movement, and long-term reliability under continuous dynamic loads.

- No middlemen

- Fast prototyping

- Private label available

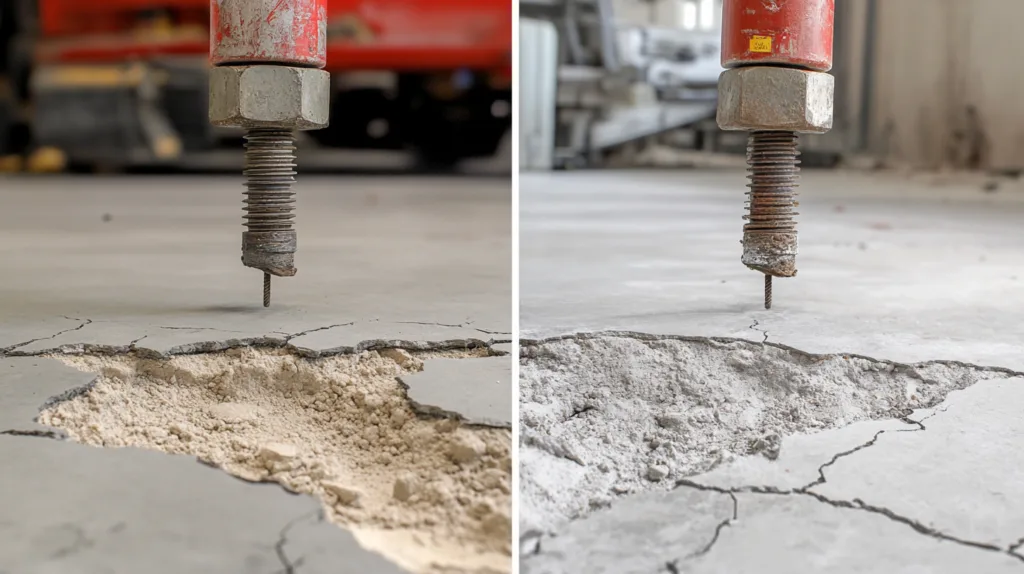

What Goes Wrong Without the Right Grout?

| Problem | Real-World Risk | ZDSpoxy Fix |

| Cement grout cracks or shrinks | Alignment loss, anchor loosening | ZDS1410AB / ZDS4130AB (high strength, no shrink) |

| Voids under baseplate | Vibration amplification, fatigue failure | ZDS3382AB (low viscosity, complete fill) |

| Heat buildup from compressor | Grout softening or cracking | ZDS4120AB (low exotherm, heat-resistant) |

| Oil-contaminated concrete | Bond failure or grout delamination | Prime with ZDS2870AB before pouring |

Recommended ZDSpoxy Systems

| Model ID | Key Feature | Ideal Equipment Type |

| ZDS1410AB | >100 MPa compressive strength | Rotary crusher, reciprocating compressor |

| ZDS4130AB | High flow + zero shrink | Large compressor skids, crusher decks |

| ZDS3382AB | Thin-gap, low-viscosity epoxy | Anchor bolts, soleplate gap injection |

| ZDS4120AB | Heat-resistant epoxy grout (up to 160°C) | Motor-driven systems, heat-generating bases |

Typical Grouted Equipment

- Rotary and jaw crushers

- Reciprocating, rotary screw compressors

- Blowers and vacuum pumps

- Hammer mills and impact crushers

- Centrifugal compressors

- Base-mounted motor-pump sets

- Skid-mounted package systems

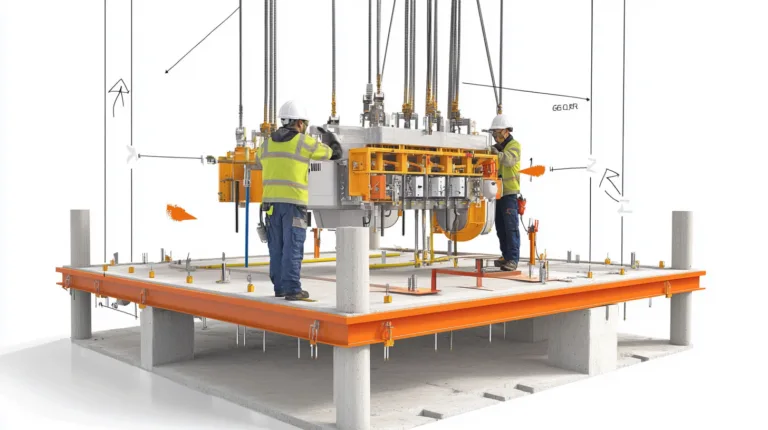

Installation Considerations

- Formwork: Must be oil-tight and vibration-proof

- Pour Method: Use headbox or side funnel to prevent air pockets

- Substrate: Prime with ZDS2870AB on damp or oily concrete

- Mixing: Low-speed mechanical mixer only (avoid air)

- Curing: Protect from vibration, impact, or heat shock for 48h

Field Example

Crushers crush. Compressors vibrate. Foundations must hold.

ZDSpoxy epoxy grouts are built for the beating—high impact, zero shrink, long-term bond.