Anti-Static & ESD Epoxy Flooring System

Anti-Static & ESD Epoxy Flooring Solutions

- No middlemen

- Fast prototyping

- Private label available

Where ESD flooring is commonly used

- Electronics assembly lines and SMT workshops

- Data centers and server rooms

- Cleanrooms and laboratories

- Pharmaceutical and medical production areas

- Areas with static-sensitive equipment or strict QA requirements

If you’re not sure, tell us your use case. We’ll recommend the right resistance range and build-up.

Key performance targets (what this system is built to achieve)

Typical targets for a well-designed ESD epoxy flooring system include:

- Surface resistance: 10^5–10^9 Ω

- Static dissipation time: < 2 seconds

- Strong bond to concrete: designed to resist peeling and delamination

- Wear resistance: suitable for daily traffic and cleaning

- Slip control: safer walking and operation

- Chemical tolerance: helps resist common cleaners and mild chemical contact

Your final results depend on substrate condition, grounding design, thickness, and installation quality.

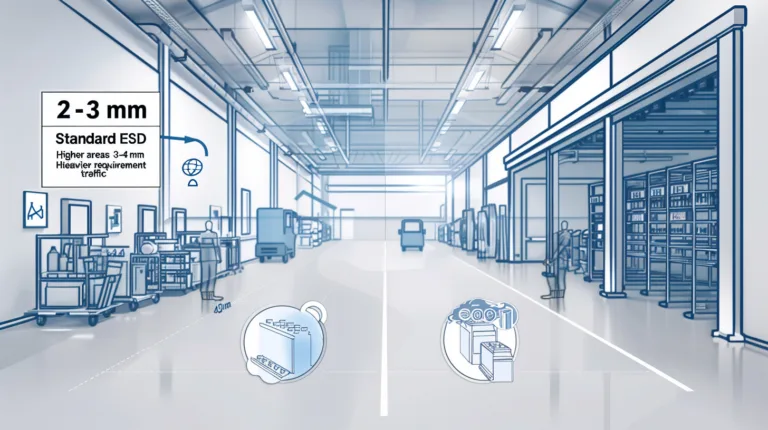

Thickness guide (simple selection)

Most projects fall into these ranges:

- 2–3 mm: standard ESD areas (people + light carts)

- 3–4 mm: higher requirements or heavier traffic (frequent carts, more impact, tougher duty)

If your slab is weak or uneven, you may need extra leveling to reach stable performance.

System build-up (layer by layer)

A reliable ESD floor needs a layered structure that works together:

- Concrete substrate (prepared and repaired)

- Conductive primer (seals concrete and supports conductivity)

- Middle coat / mortar layer (adds strength and thickness)

- Copper foil grid + grounding design (the conductive “road” to ground)

- Conductive putty (connects the grid and improves continuity)

- ESD epoxy finish / topcoat (final protective surface)

This structure is why ESD floors are stable over time—not only on day one.

Recommended product models (ZDSpoxy system match)

Recommended models by layer

| Layer | What it does | Recommended ZDSpoxy model |

| Conductive Primer | Seals substrate + supports conductivity | ZDS2103AB — Conductive Primer |

| Mortar / Middle Coat | Builds thickness, improves strength and flatness | ZDS2102AB — Epoxy Mortar Middle Coat |

| Conductive Putty | Improves conductivity continuity and abrasion resistance | ZDS2104AB — Conductive Putty |

| ESD Finish / Topcoat | Final protective layer: wear resistance + easy cleaning | ZDS5503AB — ESD Epoxy Colored Topcoat |

Optional system options (based on your site)

- Low-VOC preference (for occupied buildings or stricter indoor requirements)

- Higher wear focus (forklift paths, heavy cart lanes)

- Faster return-to-service (tight project schedules)

Tell us your schedule and traffic level, and we’ll tune the system.

Installation overview (what to expect on-site)

Site check

Confirm the target resistance range, traffic load, and cleaning method.Surface preparation

Grinding or shot blasting removes weak layers. Cracks and joints are repaired.Apply conductive primer

This seals the slab and prepares the system.Build the middle coat / mortar layer

This creates a strong, flat base for stable ESD performance.Lay copper foil grid + grounding points

This step is key. Poor grounding often causes unstable readings later.Apply conductive putty and finish layers

This connects the grid and forms the final ESD working surface.Curing and handover

Return-to-service time depends on temperature and ventilation. We will provide a clear curing plan.

Quality checks (how you verify performance)

For most projects, these checks are used at handover:

- Surface resistance test (multiple points across the floor)

- Dissipation time (if required by your process)

- Adhesion / bond quality (especially at repaired areas)

- Visual inspection (pinholes, bubbles, uneven gloss, scratches)

- Grounding continuity (common cause of ESD failure if ignored)

If you need a full acceptance checklist, we can provide one that matches your industry workflow.

Common problems (and how we avoid them)

Problem: Resistance readings are unstable

Usually caused by poor grounding design, missing connections, or uneven layers.

Problem: Peeling or bubbles

Often caused by moisture, weak concrete, or poor surface prep.

Problem: Too slippery or too rough

Finish texture should match your traffic and cleaning needs.

We help you avoid these issues by confirming the slab condition, selecting the right build-up, and providing a clear installation spec.

FAQs

Is anti-static flooring the same as ESD flooring?

What resistance range do I need?

Do I really need copper foil and grounding?

Can this be used in cleanrooms?

Get a recommendation

Tell us these 3 details and we’ll recommend the right ESD system:

- Area type (electronics / cleanroom / data center / other)

- Traffic (people, carts, forklifts)

- Your target (resistance range + finish preference)

ZDSpoxy can supply the full ESD epoxy flooring system with matching product models and a clear build-up plan for your project.