Flooring Resin Systems: Find the Right System for Your Site

What is a flooring resin system?

A flooring resin system is a layered floor build-up applied over concrete. It is designed to solve one or more problems:

- Control static electricity (ESD)

- Handle heavy traffic and forklifts

- Resist acid, alkali, or aggressive chemicals

- Improve hygiene with antimicrobial protection

- Create decorative finishes for public and retail spaces

- Build permeable resin bound stone surfaces outdoors

A good system is not “one coat of paint.” It is the right layers, the right thickness, and the right installation method.

Quick selector: choose by your main problem

Use this fast guide to pick the best direction:

- Static-sensitive areas (electronics, cleanrooms) → ESD / Anti-Static Epoxy

- Forklifts and heavy rolling traffic → Wear-Resistant PU

- Acid/alkali exposure and frequent cleaning → Chemical Resistant

- Harsh chemicals, pooling, higher severity risk → Corrosion Resistant

- Food, pharma, hygiene-focused sites → Antimicrobial

- Outdoor permeable stone surfaces → Resin Bound Stone

- Design-focused, modern finishes → Decorative Solutions

If you’re not sure, send us your site info and we’ll recommend a safe option.

Our flooring resin solutions

Anti-Static & ESD Epoxy Flooring

Best for: electronics manufacturing, data rooms, labs, clean environments

What it solves: controls static with a grounded conductive structure

Common thickness: 2–4 mm

Go to page: Anti-Static & ESD Epoxy Flooring

Wear-Resistant PU Resin Flooring

Best for: warehouses, workshops, forklift lanes, turning zones, ramps

What it solves: reduces wear, wheel marks, and impact damage under heavy traffic

Common thickness: 2–4 mm

Go to page: Wear-Resistant PU Resin Flooring

Chemical Resistant Resin Flooring

Best for: electroplating, chemical handling zones, battery/electronics process areas

What it solves: helps resist acid/alkali splashes, routine chemical cleaning, and process liquids

Common thickness: 2.0–3.0 mm

Go to page: Chemical Resistant Resin Flooring

Corrosion Resistant Resin Flooring

Best for: harsh chemical areas, higher-risk zones, frequent spills, pooling or long wet contact

What it solves: dense barrier protection where standard coatings fail early

Common thickness: 2–6 mm

Go to page: Corrosion-Resistant Resin Flooring

Antimicrobial Resin Flooring

Best for: food processing, GMP/pharma, labs, hygiene-controlled production

What it solves: supports cleaner environments with a seamless, low-porosity surface

Common thickness: 2.0–3.0 mm

Go to page: Antimicrobial Resin Flooring

Resin Bound Stone Systems

Best for: outdoor paths, driveways, public areas, pool surrounds, landscape surfaces

What it solves: creates a durable, attractive, permeable stone surface using a primer + binder + sealer concept

Go to page: Resin Bound Stone Systems

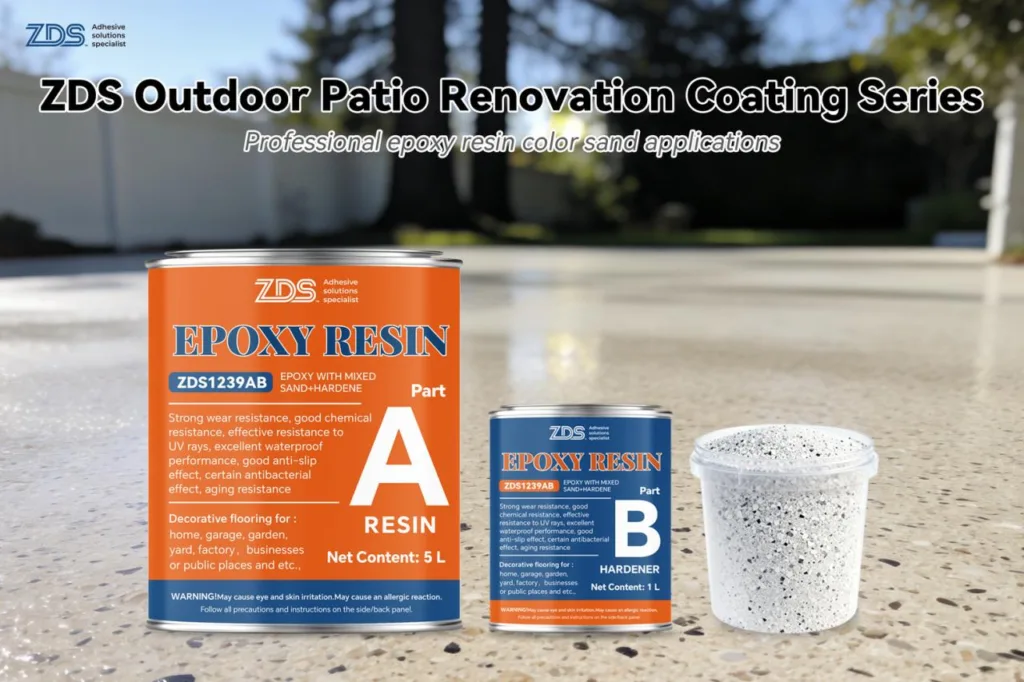

Decorative Flooring Solutions

Best for: retail, showrooms, public spaces, lobbies, modern commercial interiors

What it solves: improves appearance with finishes like flakes, metallic looks, and protective clear coats

Go to page: Decorative Flooring Solutions

How to choose the right resin system (simple framework)

Where is the floor?

What traffic will it take?

Will it see chemicals or aggressive cleaning?

Any special requirement?

What you get from ZDSpoxy

As a resin flooring manufacturer and supplier, we help you reduce risk with:

- System matching: choose the right resin type and build-up for your conditions

- Custom options: thickness, anti-slip level, finish look, and working time can be adjusted

- Quality guidance: key checks to verify performance before handover

- Stable supply: consistent product sets for repeat projects

- Project support: simple installation notes to avoid common failures

Whether you are a contractor, distributor, or project owner, we can support your workflow.

Need the full step-by-step? See our Installation Guide: Prep → Primer → Build-Up → Topcoat.

FAQ

How long do resin flooring systems last?

Do resin floors work on old concrete?

What is the most common reason for failure?

Can I make the floor anti-slip?

Which is better: epoxy, PU, or polyaspartic?

- Epoxy: strong, cost-effective, great for many indoor uses

- PU: often chosen for wear comfort, certain durability needs, and UV-stable finishing

- Polyaspartic: often selected when you want faster curing and strong topcoat performance

The best choice depends on traffic, chemicals, and downtime.

Get a ZDSpoxy recommendation (Fast)

Tell us these details, and we’ll suggest the best flooring resin system:

- Site type (factory, warehouse, lab, food, outdoor, etc.)

- Floor size and traffic (people, carts, forklifts)

- Chemical exposure (none / cleaning agents / acid-alkali / harsh chemicals)

- Special needs (ESD, antimicrobial, anti-slip, decorative)

- Your schedule (when you need to reopen)

We will reply with a custom system build-up, recommended thickness, and the best solution page to follow next.