Heavy Machinery Foundation Grouting

Secure, Level, and Stabilize Equipment with High-Strength Epoxy Grout

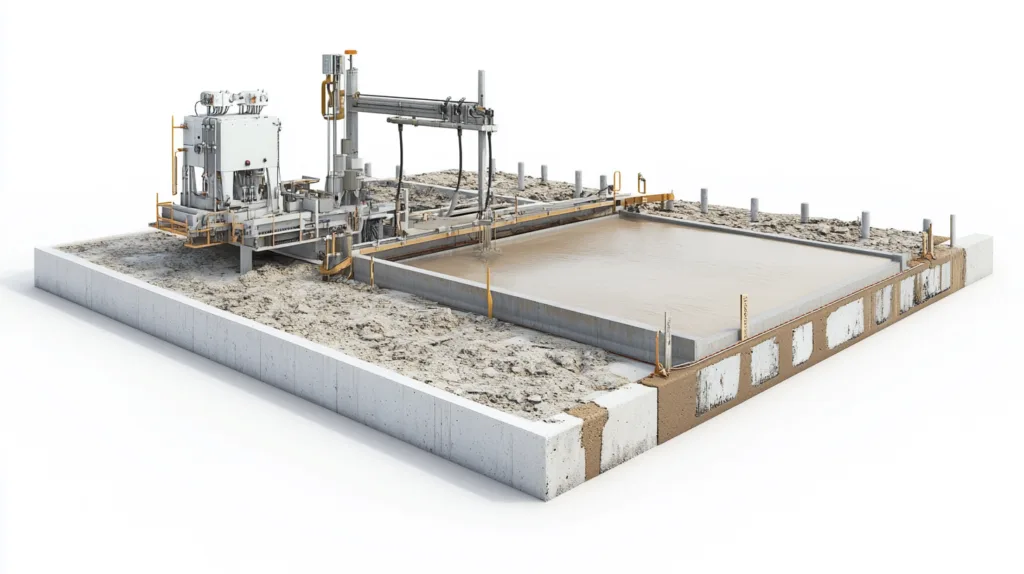

Heavy Machinery Foundation Grouting Solution

A machine is only as stable as the ground beneath it.

ZDSpoxy’s foundation grouting solutions are designed to support compressors, turbines, generators, presses, and CNC machines with high-performance epoxy systems that offer:

- >100 MPa compressive strength

- Zero shrinkage under dynamic loads

- Excellent bond to concrete & steel

- Oil, chemical, and vibration resistance

Whether you’re installing new equipment or re-grouting an aging base, ZDSpoxy offers epoxy grouts that flow into gaps, lock in alignment, and protect against long-term failure.

- No middlemen

- Fast prototyping

- Private label available

Common Foundation Grouting Problems

| Problem | Consequence | ZDSpoxy Fix |

| Cement grout cracking or shrinking | Loss of alignment, vibration | Use ZDS1410AB or ZDS4130AB (zero shrink) |

| Incomplete void fill | Hot spots, anchor loosening | Flowable epoxy (ZDS3382AB) |

| Oil or moisture contamination | Poor bond and grout lift-off | Prime with ZDS2870AB |

| Exothermic curing in thick pours | Thermal cracking, early failure | Low-exotherm grout (ZDS4120AB) |

Recommended ZDSpoxy Grout Systems

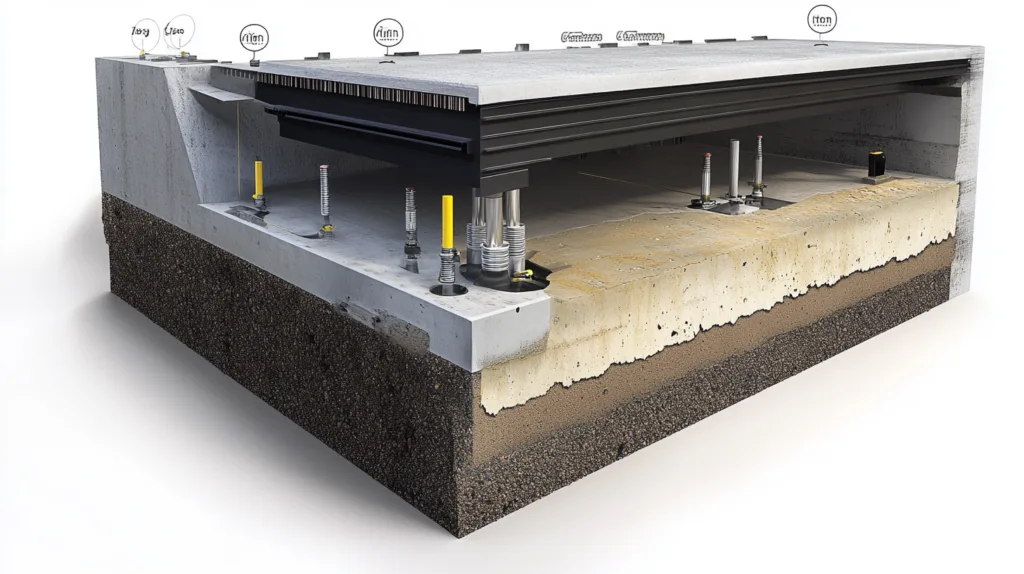

Installation Best Practices

- Surface prep: Remove oil, laitance, and dust. Use primer on moist or contaminated concrete.

- Formwork: Seal forms with tight joints. Use headbox method for best flow.

- Mixing: Use low-speed drill (avoid air bubbles). Full resin + hardener mix.

- Pouring: One-direction pour. Avoid cold joints.

- Curing: Protect for 24–48h before load. Ensure ambient temp ≥10°C.

Typical Equipment Grouted with ZDSpoxy Systems

- Compressors (reciprocating, rotary screw)

- Diesel engines & generators

- Pumps & blowers

- CNC machines & forging presses

- Crushers & vibrating screens

- Turbines & gearboxes

- Anchor bolts and soleplates

Heavy machinery deserves a solid foundation.

ZDSpoxy epoxy grout systems deliver the compressive strength, flow, and stability needed for long-term performance.