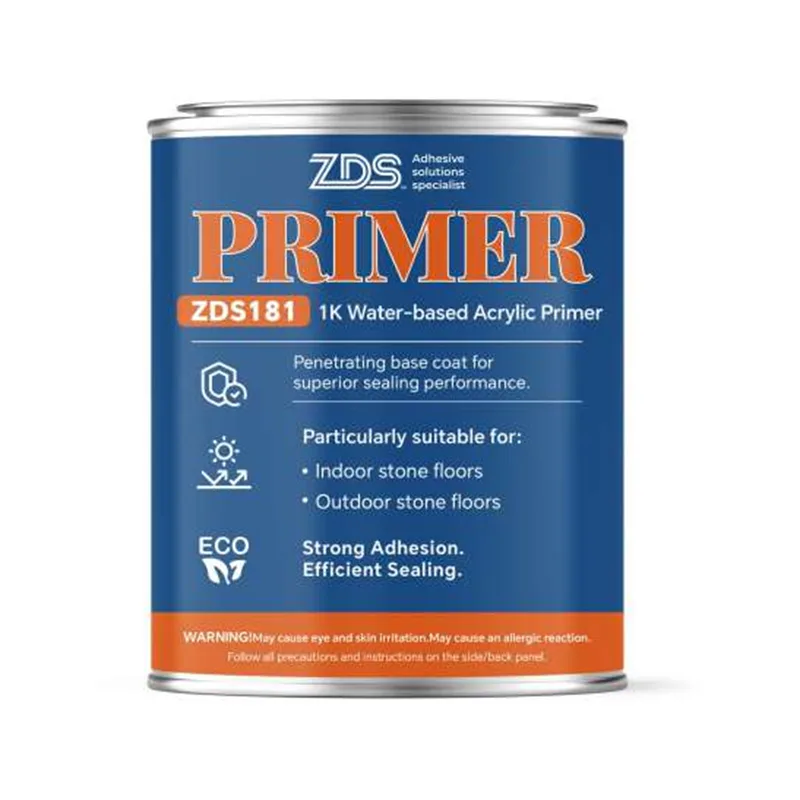

Advanced Water-Based Acrylic Primer for Concrete and Ceramic Floors

The ZDS-181 Water-Based Acrylic Primer is expertly engineered to deliver superior performance as a pretreatment solution for various interior flooring substrates. Its translucent appearance ensures excellent substrate visibility for detailed and accurate application. This fast-curing primer enhances adhesion, seals pores, and boosts the overall durability of both concrete and ceramic flooring. Designed to facilitate rapid workflow, it allows for subsequent flooring processes in as little as two hours after application.

- Strengthens substrate bonding, preventing delamination and ensuring long-lasting performance.

- Acts as a barrier against chemical corrosion, enhancing resistance to industrial chemicals and cleaning agents.

- Improves overall durability and longevity of floor finishing systems.

- Low viscosity formulation penetrates substrate pores for deeper and stronger adhesion.

Wide Range of Industrial Applications

The ZDS-181 primer is suitable for use in diverse industries, including industrial manufacturing facilities, logistics and warehousing centers, automotive workshops, food and beverage processing plants, pharmaceutical sectors, and construction and decoration aspects of infrastructure. Its user-friendly application makes it a prime choice for both seasoned professionals and DIY enthusiasts handling interior decorating projects.

- Compatible with concrete, cementitious screeds, and ceramic tiles

- Ideal for new installations or refurbishments

- Effective under conditions demanding rapid project turnaround

With its rapid curing time, enhanced surface adhesion, and chemical resistance, ZDS-181 is your optimal choice for creating robust and lasting floor systems.