High-Temperature Equipment Grouting

Epoxy Grouts That Perform at 120°C and Beyond

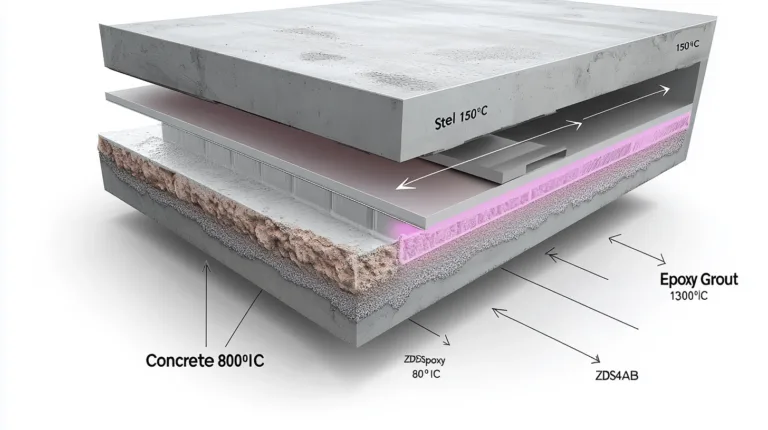

High-Temperature Equipment Grouting Solutions

Industrial equipment doesn’t always run cool.

Turbines, compressors, reactors, and furnaces generate intense, sustained heat—and if the grout beneath them fails, the whole system can shift, vibrate, or crack.

ZDSpoxy’s high-temperature epoxy grouts are built to handle the heat—literally.

With thermal resistance up to 150°C, low shrinkage, and high compressive strength, they form permanent, load-bearing bonds that stay strong in thermal cycling.

- No middlemen

- Fast prototyping

- Private label available

Why Ordinary Grouts Fail in Heat

| Common Failure | What Happens at High Temps | ZDSpoxy Advantage |

| Shrinkage | Gaps form as grout dehydrates | Thermal-stable epoxy, low shrinkage rate |

| Expansion mismatch | Cracking from differential movement | Matched modulus for steel/concrete compatibility |

| Resin breakdown | Loss of strength, crumbling | Heat-resistant epoxy resins tested to 150°C |

| Early softening | Loss of support at 70–90°C | Maintains Shore D hardness at 120°C+ |

Recommended High-Temp Grouts

Ideal Applications

- Steam turbine bases

- Chemical reactor mounts

- High-temp HVAC units

- Steel mill & foundry foundations

- Heat-generating compressors

- Petrochemical equipment skids

- Pulp & paper process lines

Installation Notes for High-Heat Zones

- Prime substrate with ZDS2870AB if moisture is present

- Mix and pour during cooler hours to reduce exotherm

- Ensure ventilation during cure (some off-gassing at 90°C+)

- Cure 48h before ramping heat load

- Control temp rise to <10°C/hour if possible

Case Highlight: Steam Turbine Base Grouting

A thermal power station in Southeast Asia installed a 1800RPM steam turbine generating 130°C at the anchor bolts.

ZDSpoxy ZDS4120AB was selected for its dual high compressive strength and resistance to heat + vibration.

After 2 years in service:

- No visible cracks or spalling

- Pull-off strength >2.8MPa

- Thermal cycling logs stable

- Certified safe in operator audit

FAQ

Will epoxy soften over time in heat?

Not with ZDSpoxy high-temp systems—they use heat-stable polymers and tested formulations for 120–150°C operation.

Can I use this for boilers or near flue gas outlets?

Yes, if direct flame contact is avoided. Surface temp must not exceed grout’s rated maximum.

Is it compatible with vibration isolators?

Yes, apply underneath or between plates. For embedment, consult anchor-specific instructions.

Designed to Withstand the Heat

ZDSpoxy helps your equipment stay grounded—even in the heat of industry.

Get grouting systems engineered for high-performance and high-temperature zones.