Oil-Soaked Concrete Crack Repair

Epoxy Injection Systems That Bond to Oil-Contaminated Surfaces

Oil-Soaked Concrete Crack Repair Solutions

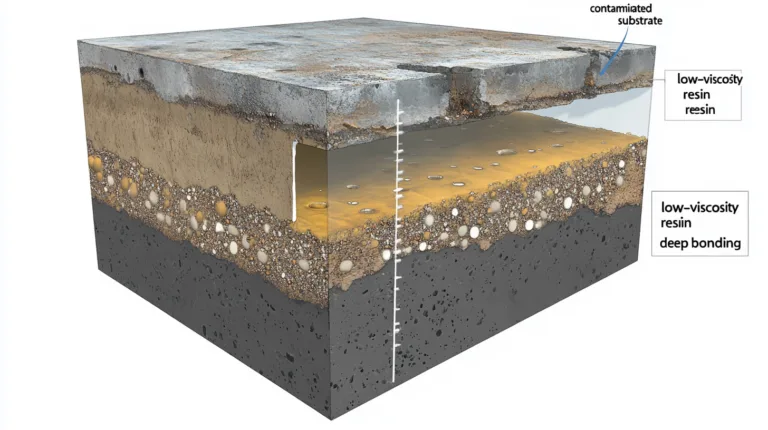

Oil spills, hydraulic leaks, and lubricant residue can permanently contaminate concrete—making traditional crack repair nearly impossible.

ZDSpoxy epoxy systems are engineered with oil-tolerant chemistry that penetrates, bonds, and cures in oil-exposed substrates, restoring strength without deep slab replacement.

Whether you’re fixing cracks in factory floors, garage slabs, or equipment bays, our systems seal from within—even in 0.02mm microcracks.

- No middlemen

- Fast prototyping

- Private label available

Why Standard Epoxy or Cement Fails on Oil-Stained Concrete

| Problem | Consequence | ZDSpoxy Solution |

| Oil in cracks or surface pores | Epoxy bead-up or curing failure | Oil-tolerant low-viscosity resin (ZDS2002AB) |

| Cement patch delamination | No bond to oil-impregnated surface | Structural epoxy injection only |

| Crack reopens after traffic | Poor filler adhesion under stress | Deep penetrating resin cures in-place |

- ✅ Works on motor oil, cutting fluid, diesel, hydraulic oil residues

- ✅ Zero shrinkage, high structural bond

- ✅ Suitable for slabs, machine pads, walls, pits, garages

Recommended Products

Where You’ll Use It

- Automotive repair shop floors

- CNC / machining workshop slabs

- Warehouse loading dock pads

- Parking garages with oil drips

- Heavy equipment maintenance areas

- Old factories with deep substrate oil

Installation Guidance

- Scrub crack area to remove surface oil (solvent, degreaser, mechanical brushing)

- Vacuum out loose debris

- Inject ZDS2002AB using twin cartridge or pump from bottom port up

- Observe full fill (resin exit at upper port)

- Allow 24–48h cure before mechanical traffic

- Finish with ZDS2771AB patch mortar if surface rebuild is needed

Real Use Case

A vehicle assembly plant had 0.1–0.3mm slab cracks below conveyor pads. Standard epoxy failed to adhere.

ZDSpoxy’s ZDS2002AB bonded into the oil-saturated concrete with no whitening or backflow. Crack was sealed without slab removal.

Traffic resumed after 48h. After 8 months: no re-cracking.

Oil isn’t the end of concrete repair.

ZDSpoxy’s injection systems go beyond surface prep—they bond through oil to restore structural performance.