Tight-Gap, Low-Viscosity Epoxy Grouting

Precision Flow for Precision Foundations

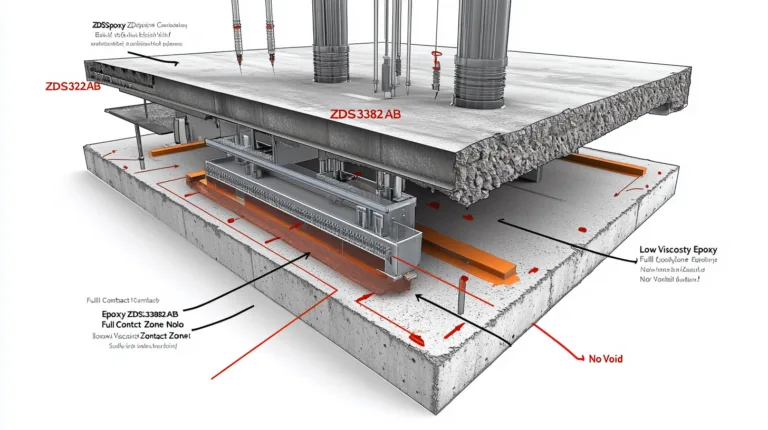

Tight-Gap, Low-Viscosity Epoxy Grouting Solutions

When machinery bases, anchors, or rails leave only 2–10mm of clearance, you need a grout that’s not just strong—but also ultra-fluid.

ZDSpoxy formulates specialty low-viscosity epoxy grouts that can self-level and flow into tight gaps without segregation or shrinkage.

No pumping. No voids. Just clean fills and full contact.

- No middlemen

- Fast prototyping

- Private label available

Why Tight Gaps Are a Challenge

| Common Issue | Resulting Problem | ZDSpoxy Solution |

| Grout too thick to enter gaps | Air voids, uneven support | Ultra-low viscosity formula |

| Pumping required | Equipment cost, inconsistent flow | Self-leveling gravity pour |

| High exothermic reaction | Thermal stress in narrow zones | Controlled heat release over time |

| Shrinkage during cure | Debonding from steel or base | Zero-shrink epoxy chemistry |

Recommended ZDSpoxy Grouts

Ideal Applications

- Slide rail & baseplate leveling

- Machine bedplates with shim gaps

- Precision robotic equipment base grouting

- Tight column grout pockets

- Anchor bolt embedments with thin sleeves

- CNC machine leveling in retrofit installs

- Laboratory or cleanroom installations

Installation Tips for Tight-Gap Grouting

- Always pre-prime tight gaps with solvent-free epoxy primer (e.g., ZDS2870AB)

- Use formwork sealant to prevent edge leakage

- Pour from one side only; allow air to vent from opposite end

- Do not over-mix—air entrainment reduces flow

- Maintain material temperature >15°C before pouring

Case Study: CNC Machine Leveling (Singapore)

A CNC retrofit contractor had to re-level a high-precision machining bed with only 4mm clearance.

ZDSpoxy ZDS3382AB was chosen for its ultra-low viscosity.

Results:

- No pumping required, pour completed in under 20 mins

- Full contact underplate confirmed via ultrasonic scan

- Compressive strength at 3 days: 84 MPa

- Client eliminated previous void-induced vibration issues

FAQs

What’s the minimum gap ZDS grout can flow into?

ZDS3382AB can flow into gaps as narrow as 1–2mm.

Is vibration or air entrapment a concern?

Not with our gravity-pour formulations. Proper formwork and venting prevent air lock.

What if gap width varies across the base?

Our thixotropic nature allows self-adjustment—grout levels automatically across gradient variations.

Don’t let tight gaps compromise your equipment stability.

ZDSpoxy’s low-viscosity epoxy grouts ensure full surface contact, zero voids, and high structural integrity—no matter how small the gap.