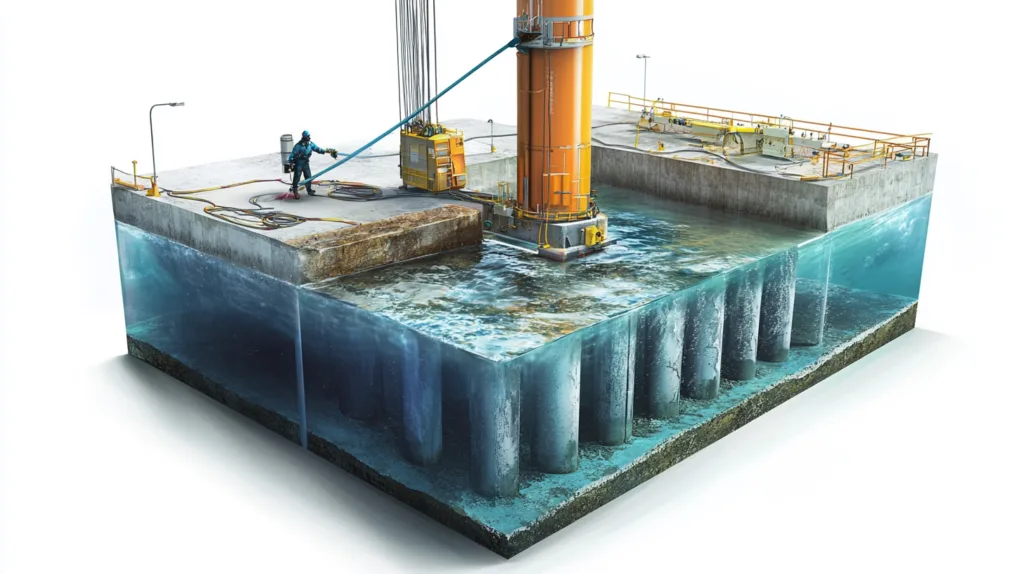

Underwater Grouting for Marine Structures

Epoxy Solutions for Piles, Seawalls, Submerged Foundations & Tidal Repairs

Underwater Grouting for Marine Structures Solutions

Saltwater, waves, and tide changes make traditional grouting nearly impossible.

ZDSpoxy offers water-curing epoxy grout systems that bond and cure directly below the waterline—no draining, tenting, or surface drying required.

From offshore pile jackets to dock foundations, our underwater epoxy grouts deliver permanent strength, anti-washout performance, and chemical resistance, even in tidal or fully submerged marine conditions.

- No middlemen

- Fast prototyping

- Private label available

Challenges of Marine Grouting

| Challenge | Risk | ZDSpoxy Solution |

| Water washout of cement grout | Loss of material, voids | ZDS1417AB – Flowable underwater epoxy grout |

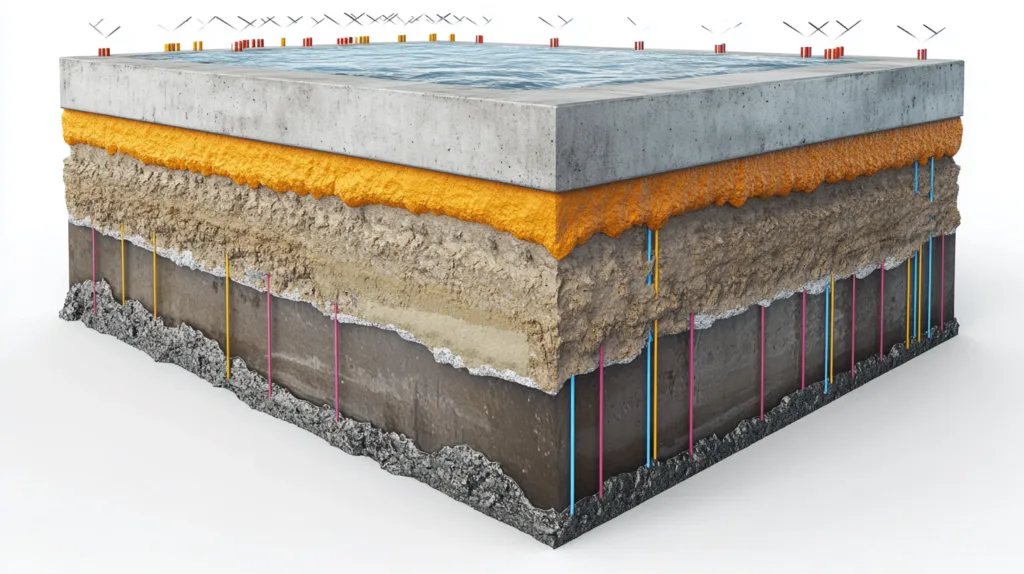

| Delamination due to moisture | Grout peeling, debonding | ZDS2870AB – Wet-tolerant primer |

| Crack injection blocked by water | Foam, curing failure | ZDS2013AB – Injectable resin for submerged cracks |

| UV + salt damage to exposed surface | Whitening, loss of durability | ZDS2186AB – Anti-yellowing underwater coating |

- ✅ 100% epoxy resin systems

- ✅ Cure underwater or on saturated concrete

- ✅ Long pot life for diver-assisted grouting

- ✅ Brush, pour, pump, or inject underwater

Typical Marine Applications

- Concrete pile jacket grouting (dock, bridge, jetty)

- Seawall crack injection or reinforcement

- Submerged slab leveling or repair

- Tidal zone pump station grouting

- Anchor bolt setting under water

- Wet concrete priming before patching/coating

- Pipeline encasement or underwater epoxy sealing

Recommended ZDSpoxy Underwater Grouts

| Model ID | Description | Best Used For |

| ZDS1417AB | Flowable grout, cures underwater | Pile jackets, submerged slab gaps |

| ZDS2013AB | Injectable resin for wet cracks | Microcracks under or near waterline |

| ZDS1007AB | Knife-grade underwater epoxy putty | Patching holes, vertical/tidal repair zones |

| ZDS2186AB | Non-whitening underwater coating | Finish layer for seawalls, ports, bridges |

| ZDS2870AB | Primer for wet, salt-exposed concrete | Enhances bond strength before overlay |

Installation Guidance

- Mix in dry zone → deliver by diver / hose / cartridge

- Apply with pump, gravity pour, or manual pack

- Use headbox or funnel for flow control

- For patch or vertical repairs, use knife-grade putty

- Primer is optional but recommended for porous or oily surfaces

- Cure underwater: 24–72h depending on temperature and model

Use Case Example

A marine contractor used ZDS1417AB for underwater pile jacket grouting at a coastal jetty (depth: 2.3m), achieving full cure within 36h despite tidal movement.

For crack sealing under a bridge deck in brackish water, ZDS2013AB was injected into 0.1–0.2mm cracks with a diver-operated twin-cartridge system. The site passed adhesion testing (pull-off >2.4 MPa) after 30 days of salt exposure.

Water should not delay your repair.

ZDSpoxy epoxy systems work where cement fails—underwater, under pressure, and under real-world conditions.