Vertical & Overhead Concrete Repair

Non-Sag Epoxy Systems for Walls, Ceilings, Beams & Soffits

Vertical & Overhead Concrete Repair Solutions

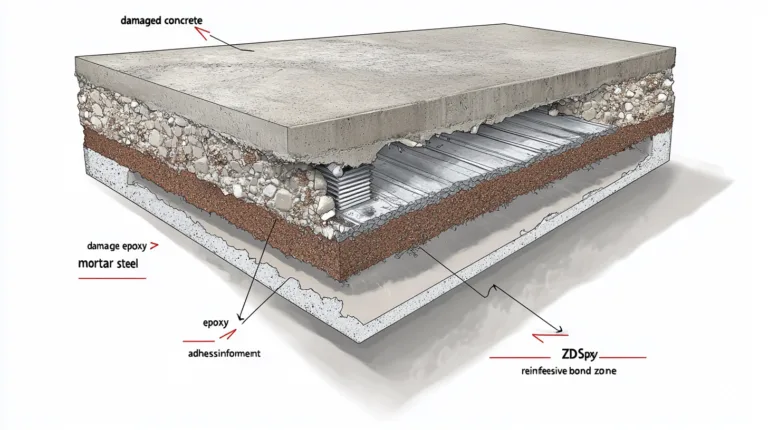

Concrete repair isn’t always flat.

Cracked, spalled, or delaminated concrete on vertical walls or overhead slabs can be a challenge—especially when gravity fights against you.

ZDSpoxy’s non-sag epoxy repair systems are formulated for knife-grade troweling, strong adhesion, and zero slump, enabling safe, clean, and lasting structural patching on any orientation—even wet or humid surfaces.

- No middlemen

- Fast prototyping

- Private label available

Common Challenges in Vertical/Overhead Repair

| Issue | Problem Result | ZDSpoxy Solution |

| Gravity-induced slumping | Material falls off or bulges | Non-sag knife-grade epoxy (ZDS2771AB) |

| Water or condensation | Bond failure, debonding over time | Moisture-tolerant primer (ZDS2870AB) |

| Poor adhesion to smooth concrete | Patch delamination or hollow sound | Structural bonding epoxy mortar |

| Difficult application overhead | Labor-intensive, high risk of material waste | Easy shaping, lightweight application |

- ✅ Strong bond to concrete, steel, masonry

- ✅ Trowelable, carveable, smooth finish

- ✅ Quick cure for faster re-opening

- ✅ Indoor/outdoor, vertical & overhead ready

- ✅ Can be topcoated or painted after curing

Recommended ZDSpoxy Systems

Typical Repair Locations

- Underbridge soffits or beam bottoms

- Parking garage ceiling spalls

- Tunnel wall and crown crack zones

- Exposed building columns with corner damage

- Precast panel edge repair

- Floor-to-wall vertical transitions

- Coastal marine structure overhangs

Installation Tips

- Clean surface (no laitance, oil, or dust)

- Use ZDS2870AB if moisture is present

- Apply mortar with trowel or knife in multiple passes

- Feather edge or rebuild edges as needed

- For overhead work, support large areas during initial set

- Full cure: 24–48h (depending on temperature)

Real Case Example

A multi-level parking garage had ceiling delamination near rebar zones.

ZDS2771AB was used to rebuild sections above head height with no slump or rebound.

After curing, surface was topcoated with waterproof membrane.

Pull-off strength >2.4MPa after 28 days.

Repair above your head—with confidence.

ZDSpoxy’s epoxy systems make vertical and overhead repair easy, clean, and long-lasting.