Expert Epoxy Repair & Restoration Solutions for Construction and OEM

Manufacturer-Direct Systems for Leaks, Cracks, and Old Surfaces

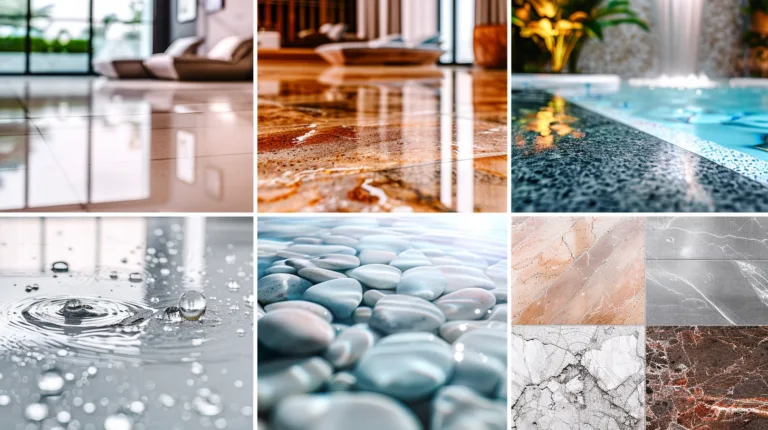

Waterproofing & Renovation Solutions

Why Choose ZDSpoxy

- Reliable lead time & global logistics

- OEM-friendly: adjustable formula, label, packaging

- Solutions for wet surfaces & extreme conditions

- Technical guidance & application know-how

- Eco-safe, fast-curing, no shrinkage options

- No middlemen

- Fast prototyping

- Private label available

Quick System Selector (30 seconds)

Choose the closest match:

- Outdoor leaks (balcony/terrace): UV + weather-resistant waterproof topcoat

- Kitchen & bathroom tiles: waterproof over tile (no demolition)

- Worn floors: choose epoxy vs PU vs polyaspartic by use and timeline

- Swimming pools: water + chemical-resistant coating system

- Exterior walls: UV-stable renovation coating

- Interior walls: low-odor renovation coating

- Courtyard stone floors: stone renovation + sealing system

- Resin bound stone (stone carpet): binder + sealer system

- Wood floors: anti-yellowing renovation varnish

Solutions by Area

Terrace / Balcony / Outdoor Floor

- Best for leaks, cracks, and outdoor wear.

- Balcony waterproofing system

Kitchen & Bathroom Tile Waterproofing

- Waterproof over existing tile with the right primer + topcoat.

- Waterproof over tile

Floor Renovation

- Compare epoxy vs PU vs polyaspartic by durability and cure time.

- Floor renovation coatings

Swimming Pool Waterproofing

- Designed for long water exposure and pool chemicals.

- Pool waterproof coating system

Exterior Wall Renovation

- UV and weather protection for exterior surfaces.

- Exterior wall renovation coating

Interior Wall Renovation

- Low-odor coatings for homes and public spaces.

- Interior wall renovation coating

Courtyard Stone Flooring

- Renovation systems for outdoor stone floors.

- Courtyard stone flooring system

Wood Floor Renovation

- Fast refresh, wear resistance, and anti-yellowing options.

- Wood floor renovation coating

Recommended Products

| Product Model | Key Benefits | Typical Use | View More |

|---|---|---|---|

| ZDS109 | 4-in-1: repair + waterproofing + wall decoration + mildew prevention; water-based; fast-drying; mildew-resistant | Wall quick repair & waterproofing paste for common wall issues | View ZDS109 |

| ZDS1002AB | Underwater curing; high chemical resistance; quick set (5–10 min); strong bonding | Underwater repairs in swimming pools; ideal for small damaged areas | View ZDS1002AB |

| ZDS1011AB | Preventive grouting; fast leak sealing; durable for renovations | Pool tile/mosaic/wall/bottom crack repair; seals joints; refurbishment | View ZDS1011AB |

| ZDS1240 | Gap-filling; durable bond; suitable for flooring | Filling gaps between wood floorboards; seamless bonding | View ZDS1240 |

| ZDS189 | Moldable & sandable; quick repair; natural wood match; versatile use | Repair damaged wood surfaces, furniture, or wood products | View ZDS189 |

| ZDS1060AB | Fungicide properties; works on damp wood; no shrinkage; hardens soft wood | Solvent-based primer for rotted wood repair (frames/pillars/furniture/decks); base for fillers | View ZDS1060AB |

| ZDS2060AB | Low odor; eco-friendly; 100% solids (no shrinkage); hardens spongy wood; seals grain ends | Solvent-free primer for wood rot repair; deep penetration; waterproof base; bonds with fillers | View ZDS2060AB |

| ZDS1010AB | Ultra-fast cure; high compressive strength; concrete-compatible; minimal downtime | Foundation crack repair in concrete; strong bonding in 5–10 minutes | View ZDS1010AB |

| ZDS115 | Flexible to handle movement; easy injection; weather-resistant; long-lasting | Medium-to-large foundation cracks; durable flexible sealing | View ZDS115 |

| ZDS1003AB | Underwater/high-humidity cure; leak-proof seal; versatile for foundations; strong adhesion | Rapid leak sealing for concrete cracks & joints; cures in 10–20 minutes | View ZDS1003AB |

| ZDS5018AB | Versatile for ceramics; strong seamless bond; household & artistic use; easy mixing | Repair ceramic tiles, tableware, fixtures, artworks; bonding broken pieces | View ZDS5018AB |

| ZDS6191AB | Non-destructive repair; deep penetration; eliminates hollowness; restores integrity | Fix hollow/detached tiles or stone without removal; high-strength restoration | View ZDS6191AB |

| ZDS5017AB | Weld-strength bond; multi-metal compatibility; quick cure; industrial-grade | Welding-like repairs for iron/steel/aluminum/copper; pipelines, machinery, automotive | View ZDS5017AB |

| ZDS2033AB | Corrosion-resistant; high-strength bond; metal-specific; durable in harsh conditions | Niobium steel repair where higher strength & corrosion resistance are needed | View ZDS2033AB |

The Simple 3-Step Method (Works for Most Projects)

Repair

Fix cracks, weak spots, loose areas, and holes first. If you skip this step, the coating can fail early.

Prime

A primer helps the coating “grab” the surface. It also seals dust and reduces bubbles.

Topcoat / Seal

This is your waterproof and wear layer. Choose clear, matte, or colored. Choose indoor or outdoor grade.

Choose the Right Material: Epoxy vs PU vs Polyaspartic

Epoxy

- Strong and stable

- Great for primers and many indoor floors

- Good chemical resistance

Best when: you want strength and value

PU (Polyurethane)

- More flexible than epoxy

- Comfortable feel, good scratch resistance

- Often lower odor options available

Polyaspartic

- Very fast cure

- Strong UV and weather resistance

- Great for outdoor projects and fast turnaround

Best when: you need speed + outdoor durability

How to Choose a System

What is the surface?

tile / concrete / stone / wood / old coating

Indoor or outdoor?

UV and weather matter outdoors

Is it wet or humid often?

bathrooms, balconies, pools

Clear or colored?

clear shows the base; colored hides marks

How fast do you need it?

fast cure vs normal cure

Installation Overview (Easy Checklist)

You don’t need to be an expert to follow the basics:

- Clean (remove oil, dust, loose parts)

- Repair cracks and weak areas

- Sand / grind if needed (for better adhesion)

- Apply primer (thin, even coat)

- Apply topcoat (follow thickness guidance)

- Let it cure (don’t rush water exposure too early)

Tip: Most failures come from poor prep or coating too thick in one pass.

OEM / ODM / Private Label Support

We can customize: formula, color, viscosity, set time, packaging size, labels, technical sheet, kit combo

Development steps: inquiry → sample → test → confirm → mass production → delivery

Quality Control: raw material checks, batch traceability, retain samples, hardness & adhesion tests

Capacity & Lead Time:

- Sample: 5-10 working days

- Mass production: 2-4 weeks (depends on model & volume)

Why work with ZDSpoxy in Europe, USA & Canada?

- Local logistics coordination & time-zone service

- Experienced with EU/US certifications (REACH, labeling, etc.)

- Support OEM clients & distributors with technical files

- Ideal for contractors & construction suppliers seeking stable quality

Why Work With ZDSpoxy

We are not a trading company. ZDSpoxy is an epoxy resin manufacturer and supplier focused on real project performance.

- Manufacturer-direct support: faster answers, fewer mistakes

- Custom options: finish, color, cure speed, and system layers

- Wholesale supply: for contractors, distributors, and project buyers

- System thinking: we help you choose the right steps, not just one product

FAQs

Can I waterproof over existing tiles?

Which is better for outdoor waterproofing: epoxy or polyaspartic?

How do I avoid peeling?

Do you offer custom and wholesale?

Let’s Start Your Project

Tell us your project details, and we’ll reply with:

- A complete system (repair + primer + topcoat)

- A simple step-by-step plan

- A manufacturer-direct quote (custom + wholesale options)

What to send us:

- Surface type (tile/concrete/stone/wood/old coating)

- Area size (sqm or sqft)

- Indoor or outdoor

- Clear / matte / colored finish

- Your timeline