Wear-Resistant Polyurethane Resin Flooring System

Wear-Resistant Polyurethane Resin Flooring Solutions

- No middlemen

- Fast prototyping

- Private label available

Where this system works best

This solution is a strong fit for:

- Factory workshops and assembly areas

- Warehouses, logistics centers, and distribution hubs

- Forklift lanes and heavy-load routes

- Parking garages and ramps

- Stations, airports, service bays, and maintenance shops

- Cold storage and food & beverage plants (when washdown and traffic are both common)

Key performance targets (what buyers care about)

A good wear-resistant PU flooring system is designed around simple, measurable goals:

- Low abrasion loss: ≤ 0.015 g (CS-17, 1000g)

- High slip safety: dry/wet friction coefficient typically ≥ 0.6

- Strong adhesion: designed to resist peeling and wheel-lift at edges

- Impact and fatigue resistance: better for repeated rolling loads

- Easy cleaning: smooth, seamless finish helps daily maintenance

Final performance depends on substrate prep, thickness, curing, and traffic conditions.

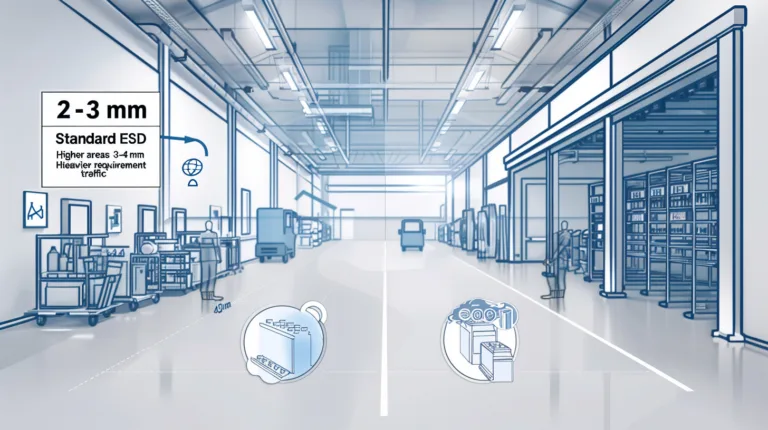

Thickness guide (simple selection)

Use thickness as a “traffic level switch”:

- 2.0–2.5 mm — medium traffic / light load

(people + light carts, general warehouse zones) - 3.0–4.0 mm — high-frequency forklift / heavy load

(forklift lanes, turning points, loading zones, ramps)

If you have point-load risks (racks, jacks, impacts), we can adjust the build-up for higher protection.

System build-up (layer by layer)

A wear-resistant PU floor is a system, not a single paint layer. Typical build-up:

- Concrete substrate (repaired + properly prepared)

- Primer (seals pores, locks dust, improves bonding)

- PU mortar / leveling layer (adds thickness, strength, and flatness)

- Wear-resistant PU topcoat (the working surface that takes the abuse)

- Optional anti-slip texture or protective sealer (based on safety + cleaning needs)

This structure is why the floor can handle rolling loads and impact over time.

Recommended product models (ZDSpoxy)

Recommended models by function

| System part | What it does | Recommended ZDSpoxy model |

| Primer (Option A) | Strong sealing + reliable bonding for industrial slabs | ZDS1012AB — 2K Epoxy Primer |

| Primer (Option B) | PU primer option for specific substrates and workflows | ZDS1901 — 1K Polyurethane Primer |

| Wear-resistant topcoat (PU) | Durable finish with strong wear + scratch resistance | ZDS6200AB — 2K Water-Based Polyurethane Topcoat |

| Optional heavy-duty topcoat (Epoxy) | High wear + strong chemical/corrosion resistance option | ZDS4220AB-90 — Industrial-Grade Epoxy Topcoat |

How to choose fast

- Want toughness + comfort + easy maintenance → prioritize PU topcoat (ZDS6200AB)

- Want extra chemical/corrosion resistance in harsh zones → consider ZDS4220AB-90 as an option in the system

- Unsure which primer fits your slab best → tell us your concrete condition and moisture risk; we’ll recommend ZDS1012AB or ZDS1901

Installation overview (what to expect)

Site check

Confirm traffic type (forklift? turning points?), cleaning method, and downtime window.Surface preparation

Grinding or shot blasting removes weak layers and opens pores for bonding. Cracks and joints are repaired.Primer application

Seals the slab and reduces pinholes and delamination risk.Build thickness (mortar / leveling)

Creates a strong, flat base—critical for rolling loads.Apply wear-resistant topcoat

This is the protective working surface.Curing and return to service

Return time depends on temperature and ventilation. We provide a clear curing plan for your schedule.

Quality checks (how you verify performance)

Before handover, we recommend checking:

- Abrasion resistance (for heavy traffic lanes)

- Slip resistance (especially ramps and wet-clean areas)

- Adhesion / bond strength (high-risk zones: repairs, edges, turning points)

- Flatness and surface finish (helps forklift stability and cleaning)

- Visual inspection (pinholes, bubbles, weak edges)

Common problems (and how we avoid them)

Problem: Wheel marks and fast wear

Fix: choose the right thickness and topcoat type for rolling loads.

Problem: Peeling at edges or joints

Fix: correct surface prep + primer selection + joint treatment.

Problem: Slippery floor

Fix: add controlled texture or anti-slip design where needed—without making cleaning hard.

FAQs

Is PU flooring better than epoxy for forklifts?

How do I choose thickness?

Can you match our downtime window?

Get a recommendation

Tell us these 4 details, and we’ll recommend the best wear-resistant system and matching product set:

- Area type (warehouse / ramp / forklift lane / workshop)

- Traffic (forklift type + frequency, cart loads)

- Cleaning method (dry, wet wash, chemicals)

- Target thickness (2–2.5mm or 3–4mm)

ZDSpoxy will propose a clear system build-up + product model list + application notes for your project.