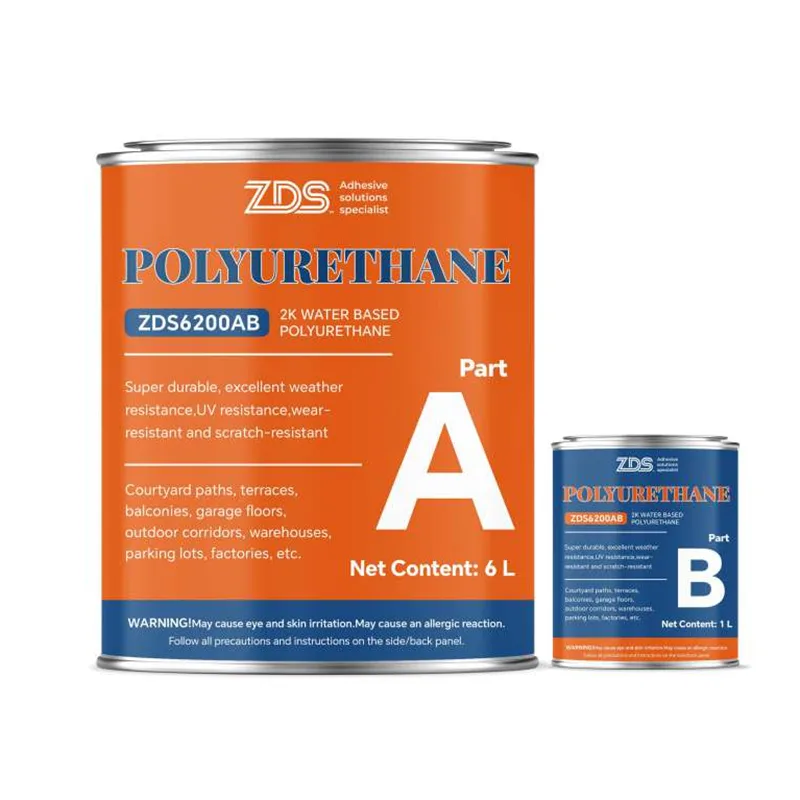

Premium 2K Water-Based Polyurethane for Industrial Flooring

ZDS-6200AB is a two-component (2K) water-based polyurethane topcoat engineered for demanding industrial-grade flooring applications. Delivering an outstanding balance of durability, environmental friendliness, and practicality, this coating sets the benchmark for professional and high-performance floor protection. Its water-based formulation ensures minimal odor and a lower environmental impact, making it highly suitable for locations with stringent eco-requirements.

Key Features and Benefits

- Exceptional Durability: Engineered for superior abrasion, wear, and scratch resistance, even in high-traffic environments.

- Advanced Weather and UV Protection: Delivers long-term color stability and gloss retention, effectively resisting UV-induced degradation and chalking.

- User-Friendly Appearance: Colored finish offers versatile aesthetic solutions, complementing various design schemes and branding requirements.

- Fast Curing Time: Formulated for accelerated curing (12-24 hours @25°C), supporting rapid construction projects.

- Eco-Friendly: Water-based, low VOC, ideal for indoor use in hospitals, cleanrooms, kitchens, and pharmaceutical factories where air quality is critical.

- Low Maintenance: Creates a surface that’s easy to clean and maintain, reducing facility downtime and upkeep costs.

Versatile Applications

- Warehouses and distribution centers

- Commercial kitchens and food processing areas

- Hospitals, healthcare, and pharmaceutical production rooms

- Shopping malls and educational institutions

- Parking lots and outdoor walkways demanding UV stability

Why Choose ZDS-6200AB?

With ZDS-6200AB, you ensure your flooring system withstands the rigors of heavy use, frequent cleaning, and exposure to sunlight, all while providing a sustainable, attractive, and reliable finish that lasts.